All electrical work must be done by a

qualifi ed electrician according to local, state

and national codes.

OPERATION:

Starting and Stopping:

1. To start the unit press the button labeled START.

2. To stop the unit press the button labeled STOP.

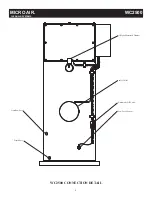

Sump Level Control:

The level of the sump is controled by measuring the static

pressure across the water in the “Digi-Helic” controller.

Factory settings for the static pressure are 2.50 In. W.C. for

SP1L, 4.00 In. W.C. for SP1H and 6.00 In. W.C. for ALHI.

These static settings will set the sump level to operate in the

10.5” to 11.5” depth range (measured when the unit is off),

and turn the motor off if the sump reaches 13.0” in depth.

The static pressure settings signal the fi ll valve when to

open and close. By adjusting the SP1L and SP1H the level

of the sump can be controlled.

1. Lowering the value of SP1L will cause the sump level

to reach a lower level before refi lling.

2. Raising the value of SP1H will cause the sump level to

reach a higher level before stopping fi lling.

To adjust the values for SP1L, SP1H or ALHI:

1. Press “SP/AL” button untill “X.XX SP1L” is

displayed.

2. Press “E” button.

3. Press arrow keys to adjust “X.XX” to the desired value.

4. Press “E” button.

5. Press “Menu” button.

Fill Valve Operation:

The fi ll valve is normally closed and only open when

signaled from the “Digi-Helic” and if the motor has been

running for longer than 30 seconds. In the event of a loss

of power the fi ll valve is designed to remain in the closed

position.

Interlocks:

Low level and motor running N.O. interlocks are provided

in the control box of the unit to interface with the controller

of the dust producing equipment. When the wet collector is

operating properly under normal conditions the interlocks

are in the closed position.

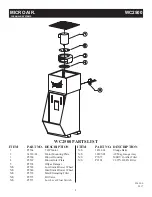

GENERAL MAINTENANCE:

1. No lubrication is required for the motor because it is a

permanent pre-lube design. Excessive dirt should be

periodically removed.

2. The sludge collection sump should be raked with the

provided tool as required.

3. When cleaning out the collection sump examine the air

intake and baffl es for material buildup.

4. Use of biodegradable additives will help in containing

any odor that may be caused from the water being

inactive over long periods of time.

CHANGING FILTERS:

CAUTION: Always make sure that the

unit is turned off before changing fi lters or

servicing the unit.

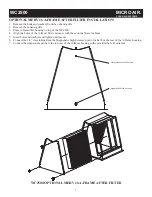

1. Remove the door from the front of the unit.

2. Remove the fi lter from the fi lter track.

3. Rinse the mist eliminator fi lter thoroughly with water,

shake dry and replace in the unit.

4. Start the unit.

WC2500

MICRO AIR

®

CLEAN AIR SYSTEMS

!

!

3