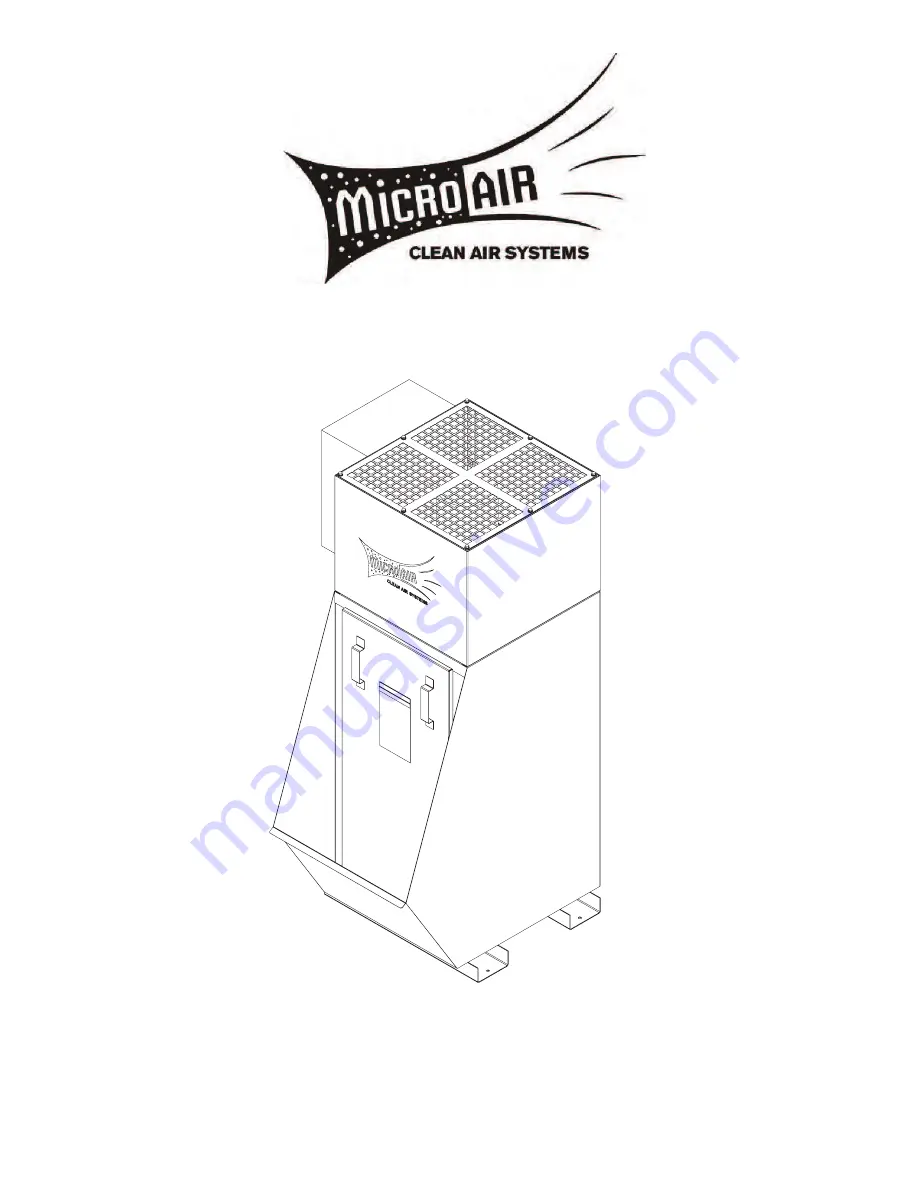

Installation and Operation Manual

Important:

This manual contains specifi c cautionary statements relative to worker safety. Read this manual thoroughly and follow

as directed. It is impossible to list all the hazards of dust control equipment. All persons involved with the equipment or

systems should be instructed how to operate in a safe manner.

MODEL WC2500