5

MIATECH TECHNICAL INSTRUCTIONS | BIO TURBO 100 USER GUIdE

MAINTENANCE GUIdE | JAN 15, 2020

Bio Turbo 100

Maintenance Guide

CAUTION:

ALWAYS UNpLUG pOWER BEfORE SERVICE!

Maintenance Requirements

Annual service requires the replacement of Air Filter

(more often if environment is very dusty) and the

replacement of the Ozone Generation Plates .

To replace the Air filter and the Ozone Generation

Plates:

• Disconnect the unit’s power cable .

• Unscrew the system lid .

• Remove and replace the air filter (#6) .

• To replace the Generator Plate (#8) release from

the holder, remove and replace with new one .

System is equipped with the Service Timer (#11) which

is counting down days to the next maintenance when

system is operating . Timer is set to 360 days and

when it gets down below 10 days it starts beeping and

Service Red LED light on the controller box will flash,

signaling maintenance is due . Service Timer has to be

reset back to 360 days after maintenance is completed .

To reset the Service Timer:

Carefully press and hold the button for about 10 sec .

until numbers will start flashing . By releasing and

pressing again the same button select 360 from

the options . Wait until it is defined (numbers will

stop flashing) .

NOTE:

a blunt object should be used to reset, so damage

won’t occur to the timer.

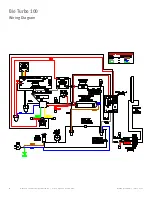

1 . Power Switch (#23132)

2 . 5 A Breaker (#23247)

3 . 24 V LED (#23291)

4 . 3 LEDs 230 V (#23193), 115 V (#23192)

5 . Service 24 V LED Red (#23292)

6 . Air Filter (#11130)

7 . Cell Disrupter (#11163)

8 . Generator Plate (#11129)

9 . Door Switch (#23233)

10 . Ozone Transformer (#23231)

11 . BT Service Timer (#23267)

12 . Solid State Relay (#23222)

13 . Fan 24 V DC (#10037)

14 . Alarm Board for Fan (#23249)

15 . Transformer

115 V (#23211) / 230 V (#23212)

16 . Catalyst Container

17 . BT Fuse Board (#23290)

18 . Timer Reset Hole

7

9

6

8

10

11

12

13

14

15

16

Diagnostic LED’s Name

Description

“Breaker” (on the Controller Chamber)

Power to the Unit

“Power IN” (on the Controller Chamber)

Power to the Power Supply

“24 V” (on the Controller Chamber)

Power to the Fan

“To the Generation Chamber”

(on the Controller Cha mber)

Power to the Generation Chamber

“Service” (on the Controller Chamber)

When the service is needed or when

protection has triggered

NOTE:

If service Red LED comes ON along with strobe light, and timer is showing

more than 10 — the ozone generation current protection might be triggered. This

could happen due to the damage of ozone plates or power jump in power supply

network. Unplug the system and check the ozone plates. If this happened because

of power jump — restart the system by switching it OFF on a remote control and

put back ON after 30 seconds.

7

9

6

8

10

12

13

14

15

16

17

18

1

2

3

4

4

4

5

11

11

Содержание BIO TURBO 100

Страница 7: ...Notes ...