Meyer Manufacturing Corporation

- 40 -

PB-MIXER-TR-MECH

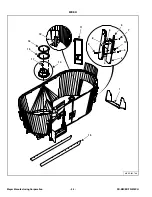

8.2.4 Knives

Knives are designed and intended for processing and mixing rations that include long stem forages.

NOTE: Some rations may require adding or removing knives, or changing knife position to obtain the desired

result.

8.2.4.1 Knife Removal

Individual knives may be removed from the auger if the ration does not include hay or includes very small amounts of

small square bale hay or tub ground hay. Removing knives will decrease the aggressive cutting action on the stem length

of the ration and may also reduce horsepower requirements.

8.2.4.2 Adding Knives

If the hay in your ration is not being processed enough or fast enough extra knives may be ordered through your dealer.

Adding extra knives will help break down and process materials faster, but may increase the horsepower required to

process and mix.

8.2.4.3 Knife Placement

The placement of knives towards the bottom of the auger will process the forage faster and make the stem length shorter

but may require more horsepower. Placement of knives higher on the auger will assist in breaking up bales faster after

initial loading.

8.2.4.4 Knife Position

“Out” Position

When the knives are in the “out” position they tend to move the long stem hay and lighter bulky materials best in the early

stages of processing and mixing. This setting may result in feed spillage in certain materials. Knives placed in this setting

are very aggressive in processing feed and will also cause an increase in horsepower requirement.

“In” Position

When the knives are in the “in” position they will slow down the long stem hay and lighter bulky materials in the early

stages of processing and mixing. Less spillage will occur due to clearance between the knives. This setting is more

desirable for heavy rations with long run time and where over processing can occur. Knives placed in this position are

less aggressive in processing feed and will reduce the horsepower requirement.

8.2.4.5 Replacing Damaged or Worn Knives

When knives become worn and rounded on the leading edge their efficiency is greatly reduced. This results in longer

processing times and increased horsepower requirements. Refer to your parts manual and contact your Meyer MFG

dealer for replacement part ordering.

Shutoff and lockout power before performing machine service,

adjusting, maintaining, or clearing an obstruction from this machine.

Refer to section 5.3 SHUTOFF & LOCKOUT POWER.

If work must be done inside the mixer put a protective cover over the

auger knives to avoid injury. The hopper and flighting may be

slippery. Use caution when stepping on or standing inside the mixer.

Содержание F585 2018

Страница 10: ...Meyer Manufacturing Corporation 10 PB MIXER TR MECH ...

Страница 12: ...Meyer Manufacturing Corporation 12 PB MIXER TR MECH ...

Страница 44: ...Meyer Manufacturing Corporation 44 PB MIXER TR MECH ...

Страница 46: ...Meyer Manufacturing Corporation 46 PB MIXER TR MECH SCALE SYSTEM PBMTR 007 4 7 8 6 5 6 5 6 9 1 2 6 5 5 10 3 ...

Страница 57: ...1 800 325 9103 PB MIXER TR MECH 57 www meyermfg com ...

Страница 58: ...Meyer Manufacturing Corporation 58 PB MIXER TR MECH DOOR FM 100 8 3 1 2 6 11 9 5 4 7 10 ...

Страница 62: ...Meyer Manufacturing Corporation 62 PB MIXER TR MECH AUGER PB 19_004 6 1 2 7 8 3 5 9 4 10 ...

Страница 66: ...Meyer Manufacturing Corporation 66 PB MIXER TR MECH RIGHT SIDE PTO GEARBOX DRIVELINE MOUNT 7 1 8 6 5 2 3 4 8 ...

Страница 68: ...Meyer Manufacturing Corporation 68 PB MIXER TR MECH LEFT SIDE PTO GEARBOX DRIVELINE MOUNT 7 8 6 5 3 9 4 8 2 1 ...

Страница 82: ...Meyer Manufacturing Corporation 82 PB MIXER TR MECH SIDE DISCHARGE SLIDE TRAY FM 125A 2 1 4 5 6 7 3 ...

Страница 86: ...Meyer Manufacturing Corporation 86 PB MIXER TR MECH REMOTE SCALE MOUNT FM 255 A 4 3 5 6 1 2 8 8 6 7 9 8 10 ...

Страница 90: ...Meyer Manufacturing Corporation 90 PB MIXER TR MECH ...