IMO

2/19

IMO-R26 EN

7

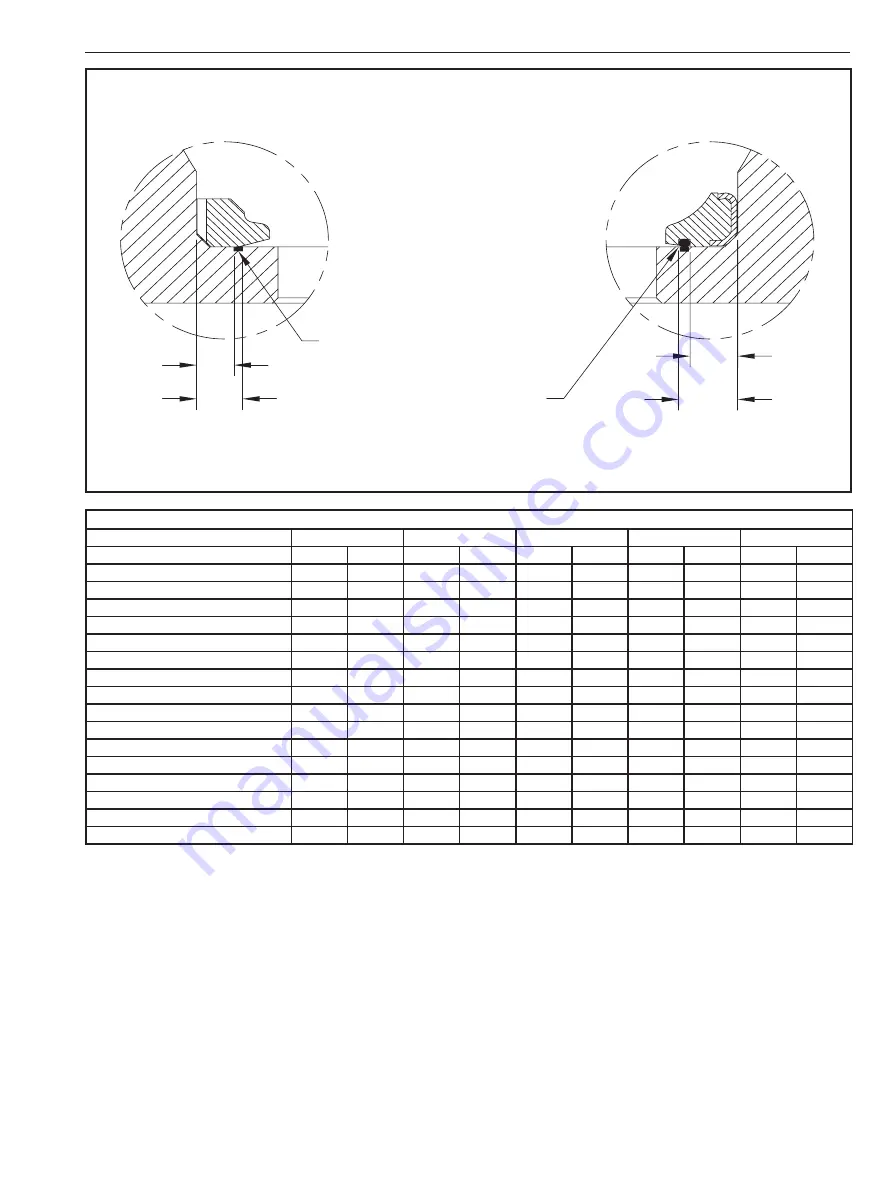

Figure 6: Seat Sealing Critical Area

Seat Sealing Area

A

B

A

B

Seat Sealing Area

Xtreme® (-9J), PTFE (-50),

MTFE (-49)

Sulphur Valve Barrier Seat

Material Code -47

(9RETS, 9RELS, SUZRC, SUZRL, SUZRS)

Table 1: Dimensions for ball valve seat cavity sealing location

Jamesbury

Size

PTFE (-50)

Xtreme

(-9J)

MTFE (-49)

W-Barrier (-47)

Railroad Ball Valves

Full

STD

Amin

Bmax

Amin

Bmax

Amin

Bmax

Amin

Bmax

6RFT

1

-

0.212

0.292

-

-

0.212

0.292

-

-

6RA3

2

-

0.180

0.260

-

-

0.180

0.260

-

-

9RFT/9FRT/9150RRR

2

-

0.181

0.259

0.176

0.264

-

-

-

-

9RFT/9FRT/9150RRR

3

-

0.274

0.356

0.274

0.356

-

-

-

-

6RIB3

4

-

0.411

0.493

-

-

0.411

0.493

-

-

9RET/9REL/9150RR

4

-

0.400

0.483

0.400

0.483

-

-

-

-

9RETS/9RELS (Sulphur Service)

4

-

-

-

-

-

-

-

0.461

0.651

5RRR/5RFF/5RFT

-

1

0.097

0.176

-

-

0.097

0.176

-

-

7RRT/7150RR

-

1

0.097

0.176

0.145

0.224

-

-

-

-

5RRU/5FRF/5ATR/5RRF/5RRT/5RNT

-

2

0.174

0.260

0.266

0.352

0.174

0.260

-

-

7RRT/7150RR

-

2

0.174

0.260

0.266

0.352

-

-

-

-

5RRF/5RRT

-

3

0.209

0.290

-

-

0.209

0.290

-

-

7RRT/7150RR

-

3

0.210

0.293

0.209

0.289

-

-

-

-

5REB3

-

4

0.249

0.330

-

-

-

-

-

-

5RET/AZFRS/AZFRC/AZFRL

-

4

0.361

0.443

-

-

0.361

0.443

-

-

SUZRS/SUZRC/SUZRL (Sulphur Service)

-

4

-

-

-

-

-

-

0.320

0.398

6.4.2 Remediating Damage

Body and Cap/Insert sealing areas may be dressed by hand

with 600 grit (minimum) sandpaper or equivalent so long as

it is applied concentric to the seal and not across the sealing

area.

For seat sealing areas that cannot be restored by hand

dressing, a one-time machining allowance of 0.010 inches

is provided on the overall seat cavity. This allowance may be

used on a single cavity or shared between the 2 seat cavities

(i.e. remove 0.010 inches on a body seat cavity or 0.005

inches on both the body and cap/insert set cavities).

When machining, care should be taken to keep the sealing

area flat and parallel with respect to the valve body joint and

provide a 125 RA maximum surface finish with a circular lay.

Bodies and caps/inserts that have been machined should

be stamped, “MCH” next to the valve tag to indicate that the

one-time machining allowance is no longer available for

repair of the valve.

The repair facility must use their own judgement and

experience when evaluating damage severity in sealing

areas. Metso recommends that all repairs be confirmed by

gas testing for shell and seat leakage. Metso’s recommend

gas test procedure is provided in

Section 7

.