12

®

EN

VECH 1001A-1002A - NLFRENES - v1.0 - 10012014

2 SPRAY GUN

2.1 Description

Your new spray gun is exceptionally rugged in construction and is built to stand up under hard, continuous use. However,

like any other fine precision instruments, its most efficient operation depends on a knowledge of its construction, operation

and maintenance. Properly handled and cared for it will produce beautiful, uniform finishing results long after other spray

guns have worn out.

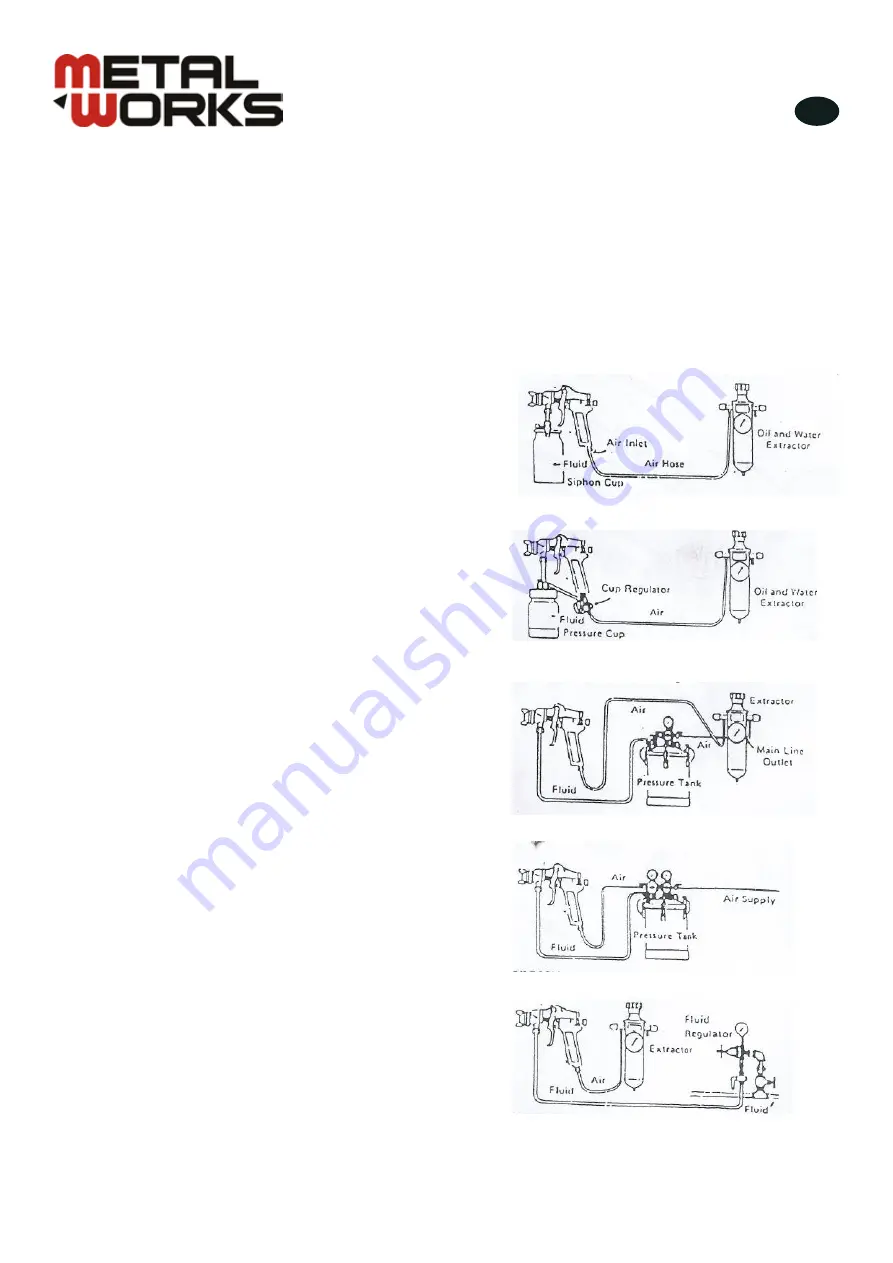

2.2 Types of installation

2.2.1 Siphon feed cup hookup

Air pressure for atomization is regulated at extractor. Amount of fluid

is adjusted by fluid control screw on gun, viscosity of paint, and air

pressure.

2.2.2 Pressure feed cup hookup

For fine finishing with limited spraying.

Air pressure for atomization is regulated at extractor, fluid pressure at

cup regulator. For heavy fluids and internal mix nozzle spraying, fluid

is adjusted by control screw on gun.

Pressure cup also available less regulator.

2.2.3 Pressure feed tank hookup

For medium production spraying.

(Single regulator)

Air pressure for atomization is regulated at extractor, fluid pressure at

tank regulator.

2.2.4 Pressure feed tank hookup

For portable painting operations.

(Double regulator)

Air pressure for atomization and fluid supply are regulated by two

individual air regulators on tank.

2.2.5 Pressure feed circulating hookup

For heavy production spraying.

Air pressure atomization is regulated at extractor, fluid pressure at fluid

regulator.

copyrighted

document

- all

rights

reserved

by

FBC