3

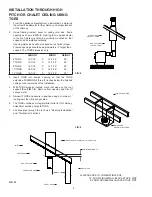

INSTALLATION THROUGH SIDE WALL

1. Locate the area where the chimney section is to penetrate

the vertical wall. Cut and frame an opening so that

the flue is centered between the vertical wall studs on 6”,

7” and 8” systems. Note that 10”, and 12” systems may

require relocation of wall studs to maintain 2” clearance

to combustibles. Consult local authorities if structural

modifications are required. Frame opening per

FIG. 5

and

Table 2

.

TABLE 2

CHIMNEY FLUE DIAMETER

6”

7”

8”

10”

12”

A

12-7/16”

13-7/16”

14-7/16”

17”

19”

B

13”

14”

15”

17”

19”

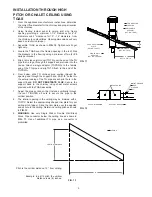

2. A wall firestop (TGWFSP) must be installed in framed

opening from the outside. Push remaining half through

opening from inside until plate is flush. Use four (4) #10 x

2 ½” wood screws to attach to opening. (See

FIG. 6

).

3. Remove wall support adaptor from TGWS box and attach

adaptor to bottom of tee by inserting into bottom of tee and

rotating to lock.

4. Insert the side tap of the tee into the opening in the wall

firestop.

5. Assemble right and left gusset to support plate using

hardware provided.

6. Attach wall support plate to wall support adaptor using 4

clamps provided. Do not tighten. (See

FIG. 6a

).

7. Align wall support with wall and secure to wall studs using

5/16” x 2” lag screws (not provided).

DO NOT SECURE TO

SIDING.

For masonry walls, use 5/16” x 2” masonry lag

bolts.

8. Install tee cap to bottom of wall support adaptor with a

minimum of two (2) #10 x ½” sheet metal screws.

9. Position tee and adapter on wall support to maintain

2” clearance to combustibles. TIGHTEN CLAMPS.

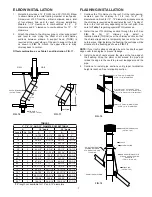

10. Slip a trim sleeve joint cover (TGTS) over the male end of

TG pipe that is to reach through the wall firestop to the tee.

Attach single wall adapter (TGPSWA) to the female end of

TG pipe and slip TGTS flush to the end of TGPSWA. (See

FIG. 7a

and

7b

.)

11. Slide Metal-Fab chimney pipe into top of tee. Align male

and female ends. Push down on pipe sections and turn

clockwise to lock. Additional chimney sections are added

and locked to a MAXIMUM OF 60 FEET. As sections are

added, it will be necessary to secure them to the outside

wall with bands (TGWB) at eight-foot intervals and 2” from

combustibles. Wall bands (TGWB) are secured to the

chimney by placing band around the chimney and tightening

clamping bolt. The assembly is anchored to the wall studs

(not the siding) with 5/8” x 2” lag bolts. To complete the

chimney installation, see “Flashing Installation” and

“Termination” sections.

A

B

FIG. 5

L944 FIG06A

LEFT

GUSSET

RIGHT GUSSET

(ATTACH GUSSETS TO

WALL STUDS USING 5/16”

X 2” LONG LAG SCREWS)

WALL SUPPORT ADAPTOR ASSEMBLY (1 EA.)

CLAMPS (4 EA.)

SUPPORT PLATE (1 EA.)

10-32 HEX NUTS & MACHINE SCREWS

SUPPLIED WITH TGWS (8 EA.)

TGTS

TGSWA

TG PIPE

TGSWA

ALIGN FLUSH WITH

EDGE OF TGSWA

TG PIPE

TGTS

FIG. 7b

FIG. 7a

AIR CLEARANCE 2”

TO COMBUSTIBLES

CHIMNEY TEE

(CAT. NO. TGT)

WALL SUPPORT

ADAPTOR

WALL SUPPORT

(CAT. NO. TGWS)

TEE CAP SUPPLIED

WITH TGT

WALL FIRESTOP

(CAT. NO. TGWFSP)

CHIMNEY PIPE

(CAT. NO. TG)

SINGLE WALL

ADAPTOR

(CAT. NO. TGSWA)

SINGLE OR

DOUBLE

WALL BLACK

STOVE PIPE

6 INCH MIN.

THRU WALLS

L

L=18” FOR SINGLE WALL BLACK STOVE PIPE

L=6” FOR DOUBLE WALL BLACK STOVE PIPE

FIG. 6

FIG. 6a