Installation and Operational Instructions for

EAS

®

-HTL housed overload clutch, Type 4190._5400

Sizes 4 and 5

(B.4.15.8.EN)

14/04/2020 TK/GH/MD/SU

Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Phone: +49 8341 804-0, Fax: +49 8341 804-421

Page 7 of 12

Installation Preparations (Customer-side)

Bore and shaft surface quality:

Ra = 1.6 µm acc. DIN 4287.

Shaft material: Yield point at least 400 N/mm

2

,

e. g. St 60, St 70, C 45, C 60.

Bore tolerance:

F7

Shaft tolerance:

k6.

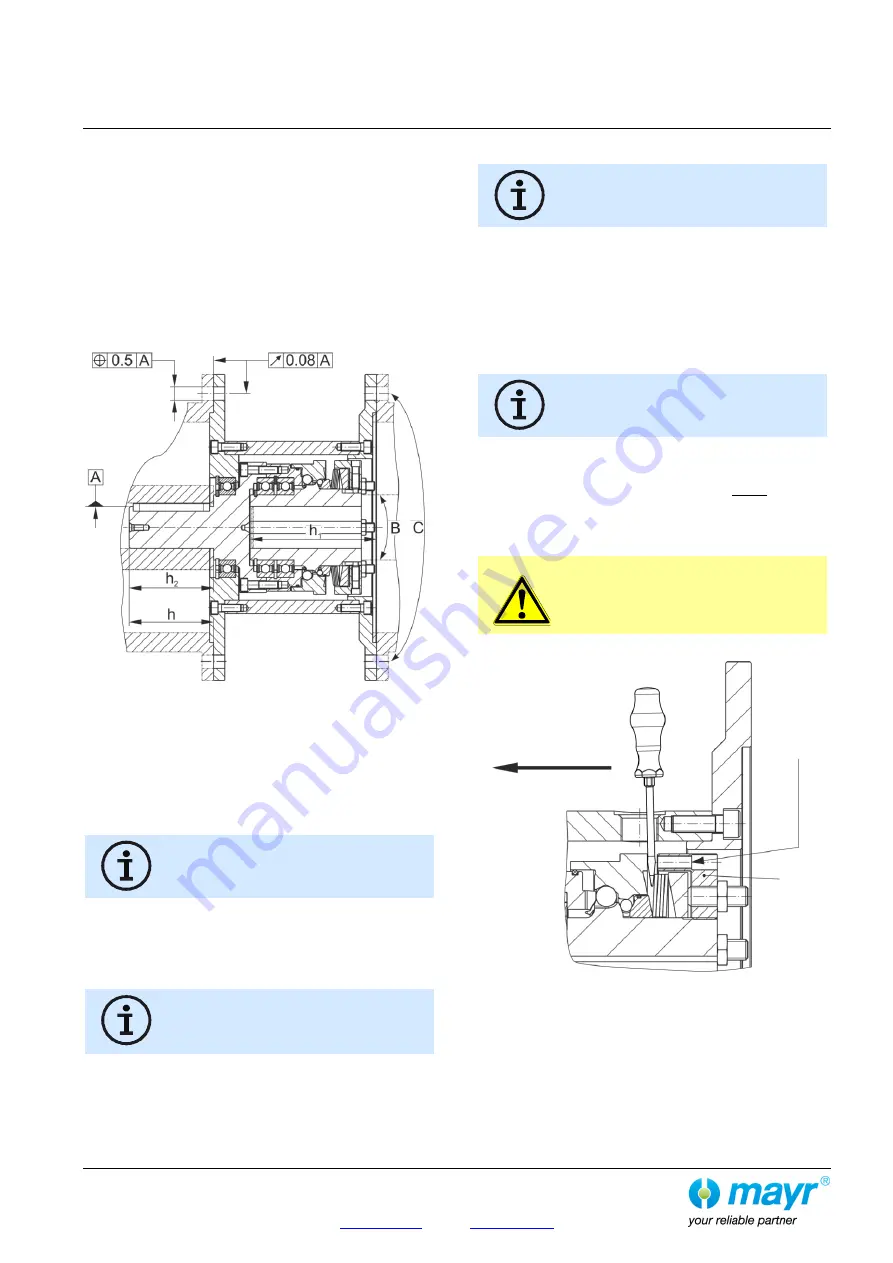

Shape and position tolerances (flange geometry):

Manufactured for clutch transmission part acc. Fig. 3.

Fig. 3

Installation (Figs. 1 to 3)

Join the manufacturer-assembled and adjusted clutch on the

output side, turn it to the correct position (flange bores must

align with the fixing threads) and bolt it together with the

mounting part (flange “Y”).

Please observe the attachment specifications indicated in

Tables 4 and 5.

Please observe clutch dimensions h and h

2

(see Table 3 and Fig. 3).

Insert flange “Z” with the shaft into the clutch hub bore (Item

1.1) or in the flange inner centring (Item 4), turn it to the

correct position (flange bores must align with the fixing holes)

and bolt it together with the mounting part (flange “Z”).

Please observe the attachment specifications indicated in

Tables 4 and 5.

Please observe the dimension h

1

(see Table 3

and Fig. 3).

The maximum permitted shaft length is:

h

1

-2 mm.

Re-engagement (Fig. 4)

Re-engagement must only take place when the

device is not running.

There are two bores (180° offset to one another) for manual

clutch re-engagement. They are locked with screw plugs (12).

In order to re-engage the clutch, at least one of the two screw

plugs (12), including its O-ring (13), must be loosened and

removed.

EAS

®

-Compact

®

overload clutch re-engagement is carried out by

applying axial pressure to the thrust washer (1.3) in the direction

of the output (flange Y) using a suitable lever tool (Fig. 4).

It may

be necessary to turn slightly between the

pressure flange (1.2)

and the thrust washer

(1.3)

.

Please make sure that the bore threads (for

screw plugs Item 12) in the distance ring (5)

are not damaged by the lever tool.

In the very high and maximum torque ranges (Types 4190.75400

and 4190.85400), engagement using a lever tool is no longer

easily possible.

Alternatively, re-engagement can take place by evenly screwing

three screws M8 (not included in the standard scope of delivery)

into the adjusting nut (Item 1.4 / Fig. 4).

On this variant, it may be

necessary to turn slightly between the

pressure flange (1.2)

and

the thrust washer

(1.3)

.

CAUTION

After re-engagement has taken place, the three

screws must be removed immediately, as they

could stop the clutch functioning (blockage).

Fig. 4

After re-engagement has been completed successfully, the

access bore must be re-closed using the screw plug (12) and

the O-ring (13) placed under it.

Flange “Y”

Output

Flange “Z”

Input

Re-engagement

direction

T

hread

for

re

-en

ga

ge

m

en

t