Installation and Operational Instructions for

EAS

®

-HT clutch Type 405_._ _400

Sizes 7

– 10

(B.4050.1.EN)

16/04/2019 TK/GH/SU

Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Tel.: +49 8341 804-0, Fax: +49 8341 804-421

Page 9 of 9

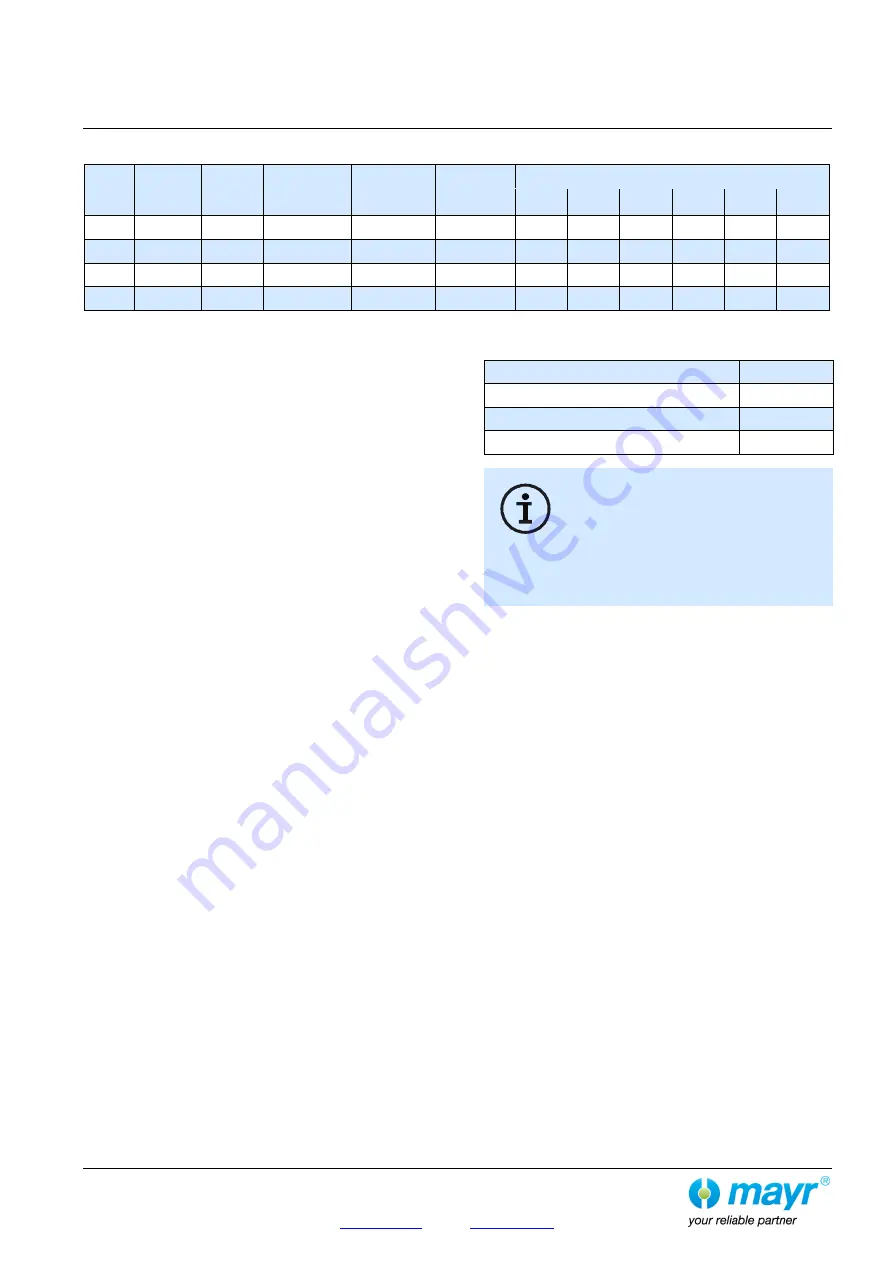

Table 3: Technical Data and Screw Tightening Torques

Size

Air gap

a

1

[mm]

Dimension

p

[mm]

Bolt

pre-tension

[mm]

Max.

radial forces

[kN]

Max.

axial forces

[kN]

Screw tightening torques [Nm]

Item 6

Item 8

Item 16 Item 20 Item 24 Item Z

7

2

8.0

0.5

+0.2

22.5

16

44

9

160

160

32

9

8

2

8.0

0.5

+0.2

30

21

76

9

240

240

32

9

9

2

8.0

0.5

+0.2

45

31.5

182

9

240

240

32

9

10

2

10.5

0.6

+0.2

60

42

182

19

490

490

63

9

Maintenance and Maintenance Intervals

Re-greasing of the overload elements (2), the bearing, the

thrust pieces (4) and the ball bearing track via the cone

lubricating nipples (Items 11, 12 and 13 / Fig. 3) at least

every 20 overload occurrences or 1x per year, see Table 4.

Maintenance work, which should be carried out after approx.

2000 operating hours, after 100 disengagements or at the

latest after 1 year, includes:

Visual inspection

Functional inspection

Inspection of the shaft-hub connection

Inspection of the screw tightening torques

The specified tightening torques (see table 3) must be

maintained.

Inspection of the set torque

Clutch release inspection

Inspection of the bearing or bearing pre-tension

Re-greasing of the overload elements (2) via the cone

lubricating nipples (11) on each overload element (2),

see Fig. 3.

Re-greasing of the bearings via the cone lubricating

nipples (Item 12 / Fig. 3) in the pressure flange (3),

2 x 180° offset.

Re-greasing of the thrust pieces (4) and the ball bearing

track via the cone lubricating nipples (Item 13 / Fig. 3) in

the pressure flange (3), 2 x 180° offset.

Clutch re-greasing must only be carried out by specially

trained personnel.

For greasing, please use NLGI Class 1.5 grease with a basic oil

viscosity of 460 mm

2

/s at 40 °C, e.g. Mobilith SHC460.

When re-installing the clutch, please secure all screws with

Loctite 243 (medium hard).

If large amounts of dirt or dust are present or in extreme ambient

conditions, it may well be necessary to carry out inspections at

shorter intervals.

We recommend that maintenance work is carried out at the

site of manufacture.

Table 4: Greasing

Lubrication points

Quantity

Item 11

2 ccm

Item 12

8 ccm

Item 13

10 ccm

On balanced clutches, please observe:

Maintaining the exact angular position between

the clutch components is absolutely necessary

for maintaining the balance quality.

On balanced clutches, the components are

therefore marked and are, on re-installation, to

be screwed together again in the

marked

angular position

to the tightening torque

according to Table 3.

Disposal

Electronic components

(Limit switch):

Products which have not been disassembled can be disposed of

under Code No. 160214 (mixed materials) or components under

Code No. 160216, or can be disposed of by a certified disposal

firm.

All steel components:

Steel scrap

(Code No. 160117)

Seals, O-rings, V-seals, elastomers:

Plastic

(Code No. 160119)