2202G1JE-DA-M-N_2010.01.

4 Operation of the Compressor and the System

Reciprocating Compressor M Series

4.2 Initial Operation

4-4

4.2 Initial

Operation

When approx. 24 hours have passed after the first startup of the compressor, foreign materials such as dust, scale,

rust, and sand in the piping can accumulate in the compressor because they flow with the refrigerant gas. Fine

foreign materials that can not be removed by the suction filter will mix into the oil, resulting in failure or

abnormal wear.

Suction of foreign materials into the compressor will continue until all foreign material has been pulled into the

compressor, the greatest amount is suctioned after the initial startup.

Presence of foreign materials can be checked by inspecting the suction filter and checking the contamination of

oil.

The oil in the crankcase can be the first sign of contamination of the refrigeration system. Therefore, if the oil

stays clear for a long period of time, it can be judged that inside of the equipment is also clean. If the oil seems to

be slightly blackened or turbid in brown, the oil is contaminated with foreign materials in the equipment.

Replace the oil as soon as possible so as to prevent foreign materials from penetrating into the sliding section of

the compressor. Take sufficient care of the following two points:

Inspection/cleaning of the filter and replacement of the oil

Cleaning of the filter may not be required when inside of the refrigerant cycle in the refrigerating,

cold storage, and air conditioning systems are clean.

Replace the oil filter elements if they are soiled. The soiled elements cannot be reused even if they

are cleaned.

Watch for any abnormal sound or temperature of the compressor.

Cleaning the oil and suction filters requires processing of the refrigerant and opening of the

compressor. For processing of the refrigerant and assembly/disassembly of the compressor,

refer to "Chapter 5. Maintenance".

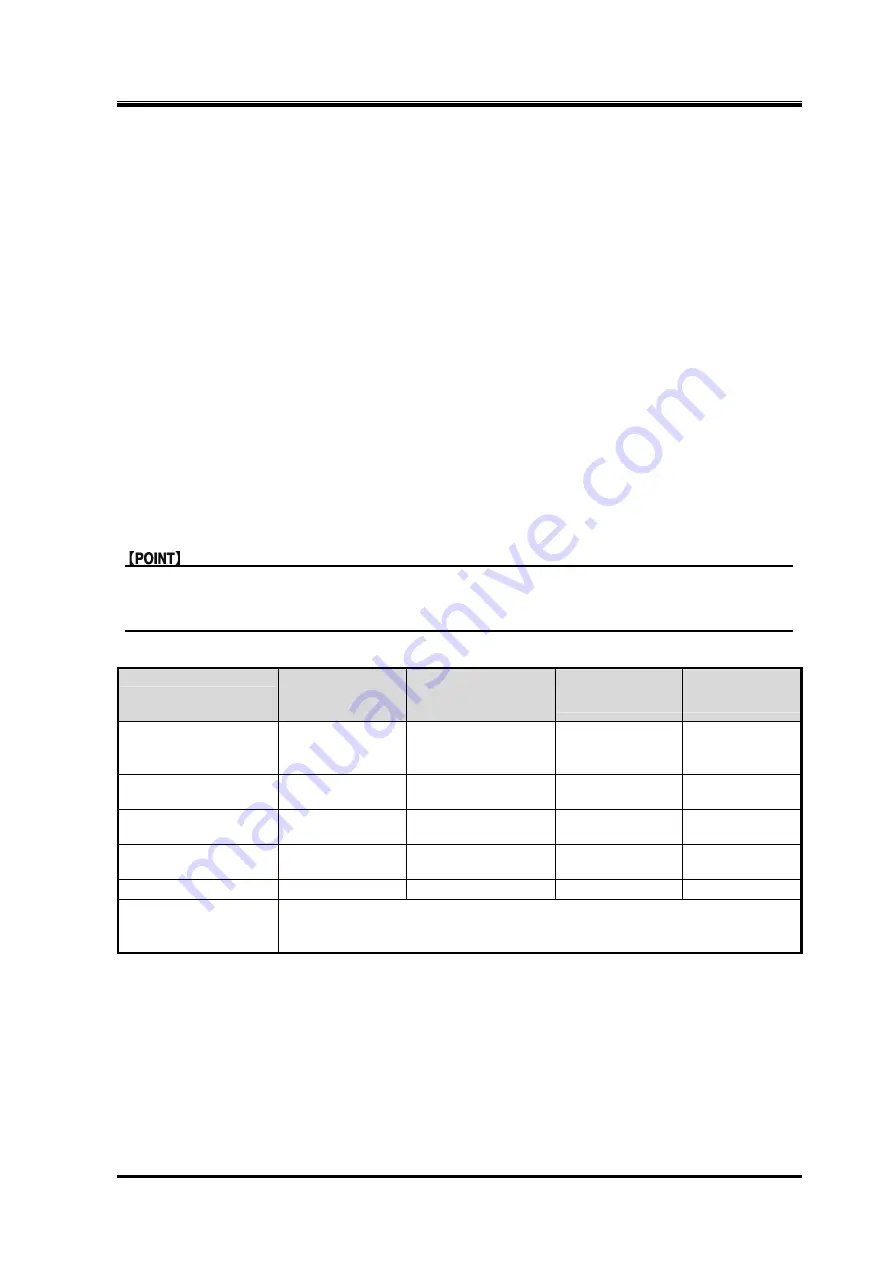

Table 4-1 Reference of the oil replacement and filter inspection

Elapsed time

Replacement of

oil and cleaning

of oil strainer

Inspection/

replacement of

oil filter

Cleaning of

suction filter

Inspection of

magnet

After completion of

refrigerant charging

operation

○

○

— —

After completion of trial

operation

○

○

○

—

100 hours after starting

operation

○

○

○

○

500 hours after starting

operation

○

○

○

○

Every 1000 hours

○

○

○

○

Note

If contamination of the refrigerant oil or clogging of the filter is found, perform oil

replacement or inspection/cleaning and replacement regardless of the above

conditions.

4.2.1 Initial Operation Method

1.

Before starting operation, rotate the crankshaft (manually) or perform inching (operation of 1—2 sec)

twice to check that the oil pressure gauge operates. Check that the both surfaces of the rotation side glass

lower slightly as well.

2.

Operate the compressor.

3.

Perform the initial operation according to "Table 4-1 Reference of the oil replacement and filter

inspection".

Содержание 4M

Страница 2: ......

Страница 18: ...2202G1JE DA M N_2010 01 Table of Contents Reciprocating Compressor M Series xvi ...

Страница 122: ...2202G1JE DA M N_2010 01 5 Maintenance Reciprocating Compressor M Series 5 5 Disassembly Assembly 5 52 ...

Страница 130: ...2202G1JE DA M N_2010 01 6 Troubleshooting Reciprocating Compressor M Series 6 1 Troubleshooting Table 6 8 ...

Страница 148: ...2202G1JE DA M N_2010 01 7 Related Document Reciprocating Compressor M Series 7 5 OHR JHR N4M N6M N8M 7 18 ...

Страница 149: ...2202G1JE DA M N_2010 01 7 Related Document Reciprocating Compressor M Series 7 5 OHR JHR N4M N6M N8M 7 19 ...

Страница 150: ...2202G1JE DA M N_2010 01 7 Related Document Reciprocating Compressor M Series 7 5 OHR JHR N4M N6M N8M 7 20 ...

Страница 151: ...2202G1JE DA M N_2010 01 7 Related Document Reciprocating Compressor M Series 7 5 OHR JHR N4M N6M N8M 7 21 ...

Страница 152: ...2202G1JE DA M N_2010 01 7 Related Document Reciprocating Compressor M Series 7 5 OHR JHR N4M N6M N8M 7 22 ...

Страница 153: ...2202G1JE DA M N_2010 01 7 Related Document Reciprocating Compressor M Series 7 5 OHR JHR N4M N6M N8M 7 23 ...

Страница 154: ...2202G1JE DA M N_2010 01 7 Related Document Reciprocating Compressor M Series 7 5 OHR JHR N4M N6M N8M 7 24 ...

Страница 155: ...2202G1JE DA M N_2010 01 7 Related Document Reciprocating Compressor M Series 7 5 OHR JHR N4M N6M N8M 7 25 ...

Страница 156: ...2202G1JE DA M N_2010 01 7 Related Document Reciprocating Compressor M Series 7 5 OHR JHR N4M N6M N8M 7 26 ...