Petroleum coke fuels or household waste should not be

burned on this appliance.

De-Ashing

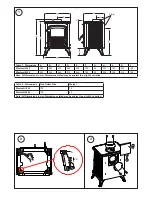

To de-ash the grate insert the notch on the riddle hand tool into the

peg on the side of the stove

(D - Fig 6)

, then draw the tool forwards

and backwards with a slow positive action

(Fig 7)

.

The ash pan should be emptied each time after operating the stove

so not to let build up of ash occur. Where possible, it is best to

wait until the stove and ash has cooled before removing the ash

pan. To remove, open the stove door by lifting the handle upward

(C - Fig 6

then using the riddle handle lift the ash pan out of the

fi

re

(Fig 8).

For ef

fi

cient burning of your appliance, make sure the

grate is clear of burnt debris; e.g. nails, etc.

Shut down Periods

If shutting down the stove for long periods (e.g. for summer months)

make sure that all ash is removed from the stove and that the

chimney

fl

ue ways and baf

fl

e plate are brushed clean. When the

stove is cold a vacuum cleaner may be used to remove any residual

ash or soot. Close the door and leave all air inlets open fully. This

action will ensure air circulation through the appliance and will help

to avoid corrosion and condensation within the appliance during

this shut down period.

Safety Notes for Your Guidance

FIRES CAN BE DANGEROUS.

Always use a

fi

re guard in the presence of children, the elderly

or the in

fi

rm. Inform all persons the dangers of high temperatures

during operation of the appliance including the stove pipe.

Use operating tools provided.

DO NOT OVER FIRE.

It is possible to

fi

re the stove beyond its design capacity. This could

damage the stove, so watch for signs of over

fi

ring. If any part of

the stove starts to glow red, the stove is in an over

fi

re situation

and the controls should be adjusted accordingly to reduce air

intake. Never leave the stove unattended for long periods without

adjusting the controls to a safe setting. Careful air supply control

should be exercised at all times.

Warning - Fume Emissions

Properly installed and operated, this appliance will not emit fumes.

Occasional fumes from de-ashing and refuelling may occur.

Persistent fume emission must not be tolerated. If fume emission

does persist, then the following immediate action must be taken:

1. Open doors and windows to ventilate the room.

2. Let the

fi

re out, or eject and safely dispose of fuel from the

appliance.

3. When the stove has cooled, check for chimney

fl

ue blockage

and clean if required.

Do not attempt to relight the

fi

re until the cause has been identi

fi

ed.

If necessary seek professional advice.

General Maintenance

Baffl e Plate

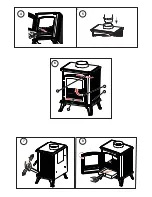

This should be removed at least once a month to prevent any

build up of soot or ash, which could lead to blocked

fl

ue ways

and dangerous fume emission. If the baf

fl

e plate is removed the

fl

ueway can be swept through the appliance.

Stove Body

The stove is

fi

nished with a heat resistant paint and this can be

cleaned with a soft brush. Do not clean while the stove is hot,

wait until it has cooled down. The

fi

nish can be renovated with a

suitable brand of paint.

Glass Panels

Clean the glass panels when cool with a proprietary glass cleaner.

Highly abrasive substances should be avoided as these can

scratch the glass and make subsequent cleaning more dif

fi

cult. Wet

logs on heated glass, a badly aimed poker or heavy slamming of

the doors could crack the glass panels. The glass will not fracture

from heat.

Flue Pipes

Check your

fl

ue pipe each year before starting to use your stove

for the winter. Birds may have nested in the

fl

ue cowl. The

fl

ue

pipe must be swept at least once a year by a Quali

fi

ed Chimney

Sweep.

To avoid a build up of soot on the baf

fl

e plate (the plate inside the

stove above the grate) it must be removed and cleaned periodically.

This plate locates the back and side

fi

rebricks so note its position

before removal. To remove, lift plate and remove one side brick;

this will allow the plate to drop and aid removal. To replace, position

baf

fl

e plate on back and side plate, lift plate and replace remaining

brick, making sure it has located in position. This must be done

when the stove is cold.

Troubleshooting

1. Poor heat output

a. Stove too small for room: Seek advice from a Quali

fi

ed Heating

Engineer as to (kW) output required for the room size. As a

guideline the volume of the room in cubic feet divided by 500;

e.g. room 15’x15’x8’ would require 3.6kW approx.

b. Chimney and/or

fl

ue pipe restricted, room ventilation restricted:

On installation these should have been checked but regular

maintenance is necessary as conditions can change; e.g. soot

build up, birds nesting, masonry fall, dust build up or furniture

blocking vents.

c. Poor quality fuel: Only burn dry seasoned timber, soft woods

have a lower heat output than hard woods per hour.

2. Dirty Glass Panel

a. Generally caused by poor fuel quality, see (1c)

b. Use secondary air slide (Airwash) for glass panel

c. Fire burning too low, open air vents on stove to create hot

fi

re;

this may ‘burn’ glass clean.

d. If glass requires cleaning use glass cleaner recommended by

your supplier; only use glass cleaner on cold glass. DO NOT

USE any abrasives or scrapers as these will scratch glass and

increase future tar build up making it harder to clean.

3. Unburnt Fuel in Firebox

Insuf

fi

cient air reaching fuel. Open primary air slide, this will supply

combustion air to burn fuel fully (unless it has reached a ‘point of

no return’)

Check if the ash pan is full and empty if required. De-ash with the

riddler to make sure the grate is not blocked and check for jammed

clinker or nails when the

fi

re is out and the stove has cooled.

- 5 -