Mas Grup

18

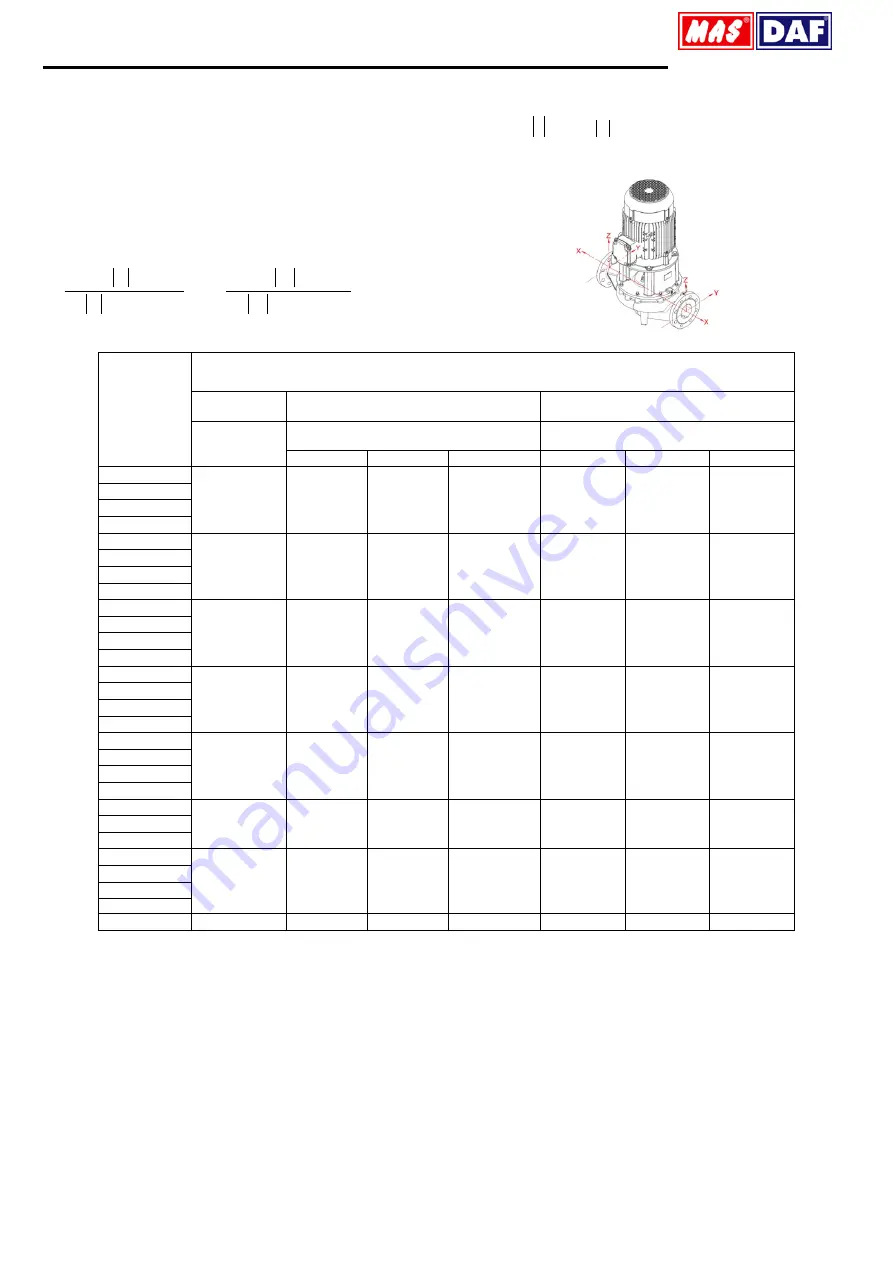

14. FORCES AND MOMENTS AT THE PUMP FLANGES

All of the applied load sif not reached the maximum allowable value, to

provide that the following additional conditions, one of these loads may

exceed the normal limit:

Any component of a force or a moment, must be limited1.4times of

the maximum allowable value,

The actual force sand moments acting on each flange, should provide

the following formula:

2

2

allowable

maximum

actual

2

allowable

maximum

actual

M

M

F

F

In here,

F

and

M

arearithmetic sum of the loads for each

flange at the pump level, without regard of the algebraic signs of the

actual and maximum allowable values.

PUMP

TYPE

FORCES AND MOMENTS

DN FLANGE

SUCTION AND DISCHARGE FLANGE

SUCTION AND DISCHARGE FLANGE

mm

N

Nm

F

y

F

z

F

x

M

y

M

z

M

x

INM-H 40-125

40

595,3

476,2

523,82

428,58

500,01

619,06

INM-H 40-160

INM 40-200

INM 40-250

INM-H 50-125

50

785,7

642,9

714,3

476,2

547,63

666,68

INM-H 50-160

INM 50-200

INM 50-250

INM-H 65-125

65

1000

809,5

880,97

523,82

571,44

714,3

INM-H 65-160

INM 65-200

INM 65-250

INM 80-160

80

1191

976,2

1071,45

547,63

619,06

761,92

INM 80-200

INM 80-250

INM 80-315

INM 100-160

100

1595

1286

1428,6

595,25

690,49

833,35

INM 100-200

INM 100-250

INM 100-315

INM 125-200

125

1881

1524

1690,51

714,3

904,78

1000

INM 125-250

INM 125-315

INM 150-200

150

2381

1929

2142,9

833,35

976,21

1190,5

INM 150-250

INM 150-315

INL 150-360

INL 200-315

200

3040,2

2440,5

2713,8

1065

1223,2

1612,4

Table 6 -

Forces and Moments at The Pump Flanges

Forces at the pump flanges were calculated according toTS EN ISO 5199 standard. The calculations are valid for the materials of cast iron and

bronze. Forces and moments at the flanges that made of stainless material will be approximately twice as moments in the table.