4

(Note 1): Please adjust R6 resistor value to fit current limiter target value.

(Current limit value) : 0.1

Ω

is mounted on this board. Iout (max) = 0.25V / R6 = 2.5A

(Note 2): Please adjust lock protection setting used R3 and R4 resistor value.

In this board, 68k

Ω

is mounted as R3, and 33k

Ω

is mounted as R4. It becomes automatic recovery mode,

and lock detection time is 1s.

(

(

(

(

Note 3

)

)

)

)

: Switches are used for OVP pin, BRAKE pin, CW/CCW pin and START pin settings.

Power ON sequence

1. In general, please set BRAKE switch to high level.

2. During start operation, please hold inputting PWM signal as low level.

3. On next step, please set to START switch to high level.

4. In case of motor drive voltage is 24V, please set to OVP pin to high

level. In case of motor drive voltage is 12V, please set to OVP pin to

low level.

5. Please supply VCC voltage (VCC voltage range is 9 to 28V.)

6. Please set to START switch as low level. (Motor starts operation.)

7. When PWM signal(speed control signal) inputs to PWM-in pin, a

motor speed changes based on PWM signal.

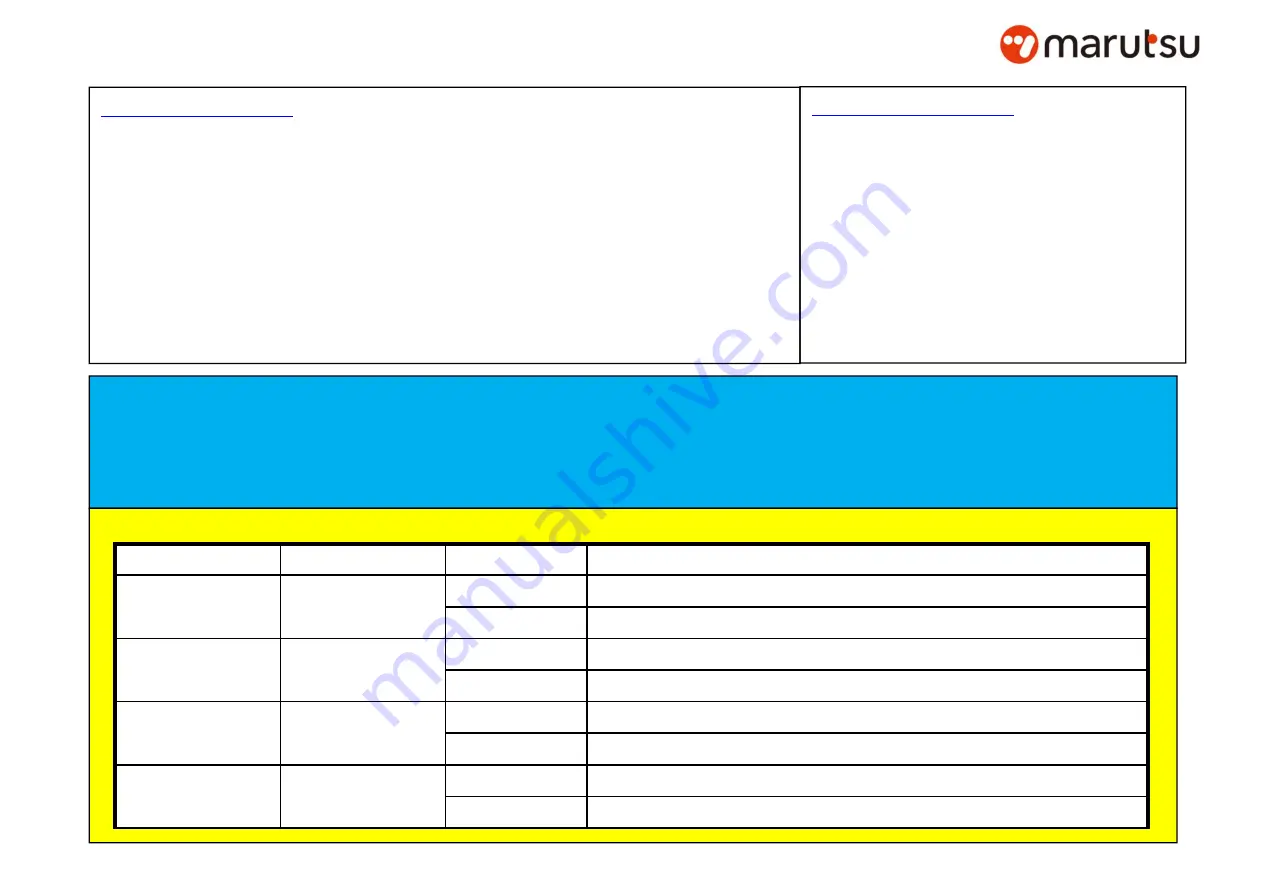

Switch name

Pin name

High/Low

Explanation

SW1

OVP

High

Motor drive voltage

:

24V

Low

Motor drive voltage

:

12V

SW2

BRAKE

High

Operation

Low

Brake

SW3

CW/CCW

High

Reverse

Low

Forward

SW4

START

High

Stop (Charge Pump circuit is stopped

)

Low

Operation (Charge Pump circuit is operation)

Power OFF sequence

1. Down PWM duty slowly, and stop

the motor rotation.

2. Set START switch to high level

position.

3. Fixed PWM signal to low level.

4. Power OFF of VCC power supply.

Power ON and power OFF sequence and notes