Martin Engineering M4101-01/19

7

Martin

®

HD QB1™ Cleaner

Installing Belt Cleaner and Tensioner

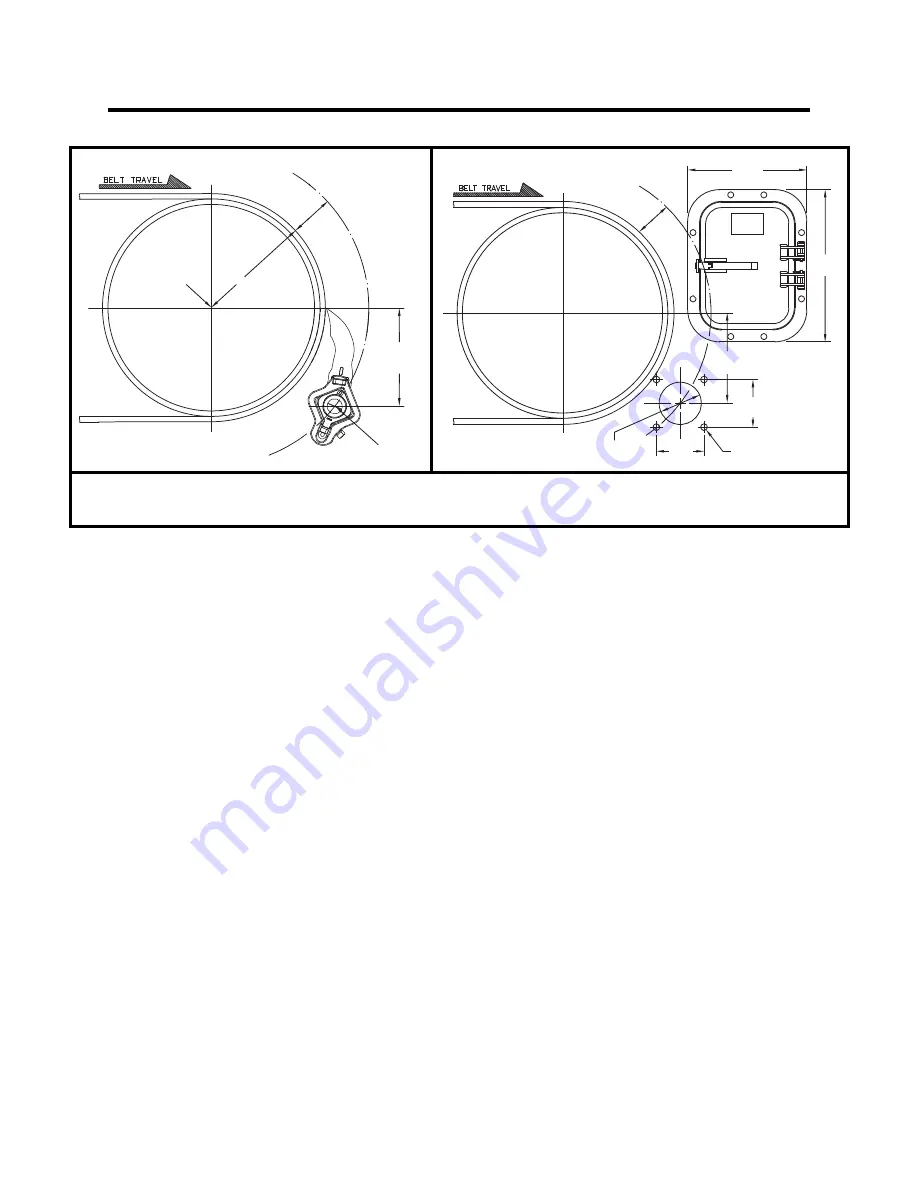

Figure 3. Belt Cleaner Mainframe Location & Chute Wall Cutouts

Locating belt

cleaner

mainframe

1. On operator side of chute, find pulley center point (A).

2. Measure radius of head pulley including lagging and belt thickness (B).

To this dimension, add 3.50 in. (89 mm).

3. Starting from center point (A), measure the total distance calculated in

step 2 (B + 3.50) and draw an arc on chute wall.

4. Measure down from pulley's horizontal centerline the distance shown in

Figure 3 and draw a horizontal line parallel to it. Locate center point of

belt cleaner mainframe (C) where this line intersects the arc on the chute

wall.

5. Make sure mainframe and blade do not lie in path of material unloading

from conveyor belt.

6. Repeat steps 1 through 5 for far side chute wall.

7. Drill or cut holes for tensioner mounting plates on chute walls as follows:

a. If bolting tensioner mounting plates to chute walls, do the following:

(1) Drill or cut one 4-in. hole for mainframe and four 5/8-in. holes for

screws in both operator side and far side chute walls. Remove

burrs and sharp edges.

b. If welding tensioner mounting plates to chute walls, do the following:

(1) Drill or cut one 4-in. hole for mainframe in both operator side and

far side chute walls. Remove burrs and sharp edges.

8. If using Martin

®

Inspection Door, cut access door opening and mounting

holes according to

Martin

®

Inspection Door Operator's Manual

,

P/N M3891.

Center point of pulley

Center point of belt

Radius of head pulley

A.

B.

C.

including lagging and belt

cleaner mainframe

8.50

(216)

minimum

B

3.50

(89)

A

C

Ø4.00

(102)

4.50

(114)

Ø0.625

(16)

4.50

(114)

8.50 (216)

minimum

3.50

(89)

14.39

(365)

11.26

(286)

Installation

Содержание HD QB1

Страница 1: ...Martin HD QB1 Cleaner Operator s Manual M4101 Go to Martin HD QB1 Cleaner web page...

Страница 22: ......