13

FAN

–Inspect fan blade surfaces every six months. For detailed maintenance informa-

tion, refer to the Fan User Manual.

GEAREDUCER

–Make weekly and monthly oil checks. Inspect internal parts during

seasonal oil change. Refer to the Geareducer User Manual

for detailed maintenance

instructions.

DRY DAMPERS

–Inspect linkages, adjust and lubricate as needed.

VENT DOORS

–Inspect linkages and bearings, adjust and lubricate as needed.

PAINTING

–Periodically clean and, if necessary, recoat all metal parts subject to corrosion.

Water Quality and Blowdown

BLOWDOWN

–Blowdown, or bleed-off, is the continuous removal of a portion of the

water from the circulating system. Blowdown is used to prevent the dissolved solids

from concentrating to the point where they will form scale. The amount of blowdown

required depends upon the cooling range (the difference between the hot and cold

water temperatures), the composition of the make-up water (water added to the sys-

tem to compensate for losses by blowdown, evaporation and drift). and the amount

of condensed water returned from the ClearSky heat exchanger modules. The follow-

ing table shows an approximate amount of blowdown required to maintain different

concentrations with various cooling ranges—these numbers are reduced by the % of

condensed water at a given weather condition:

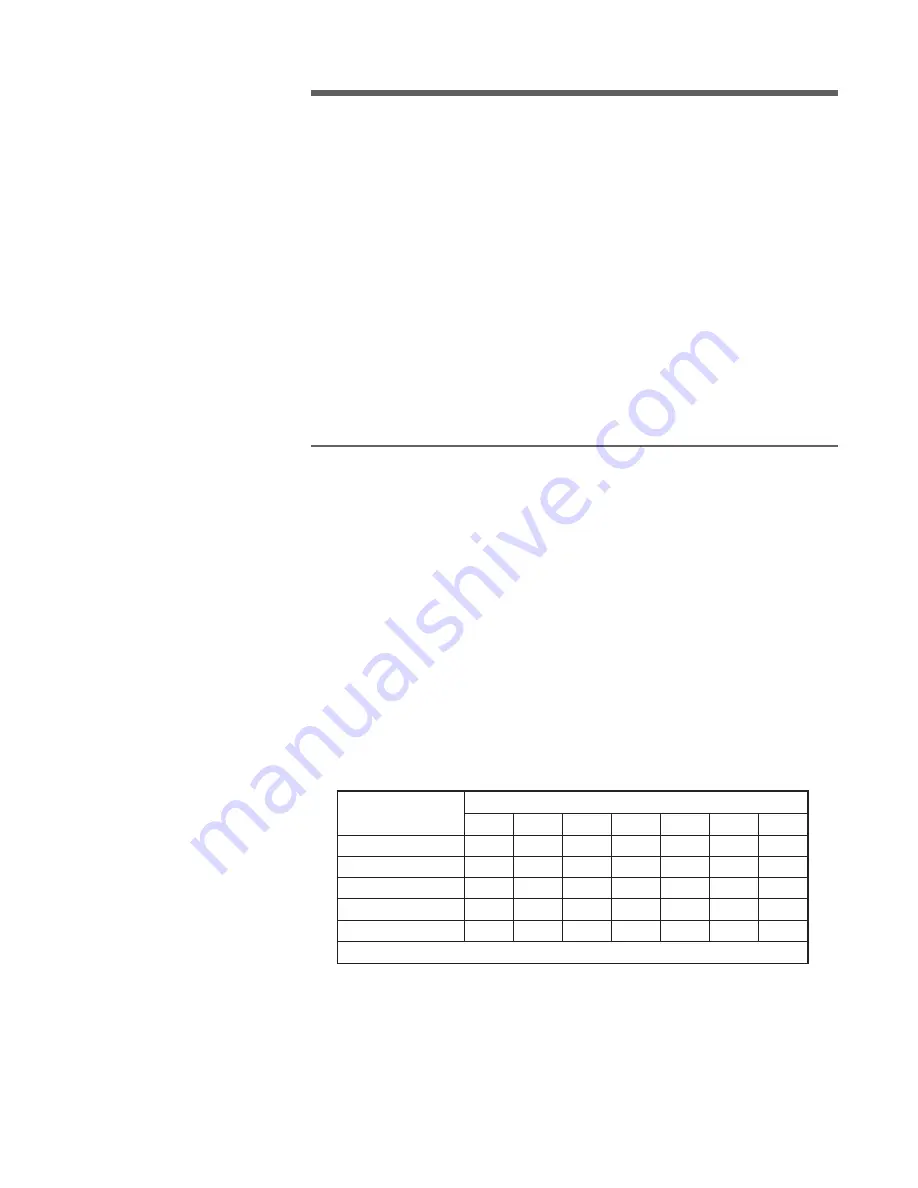

BLOWDOWN–% OF CIRCULATING RATE

EXAMPLE:

7000 gpm circulating rate, 15° cooling range. To maintain 4 concentra-

tions, the required blowdown is .38% or .0038 times 7000 gpm which is 26.6 gpm.

Cooling Range

Number of Concentrations

X

5

.

1

X

0

.

2

X

5

.

2

X

0

.

3

X

0

.

4

X

0

.

5

X

0

.

6

.78

3°C

6°C

9°C

12°C

14°C

1.58

2.38

3.18

3.98

3

.

5

2

.

8

1

.

1

1

.

8

0

.

6

0

.

7

.

1

5

.

8

3

.

5

2

.

8

1

.

4

1

.

1

.

1

8

7

.

8

5

.

8

3

.

8

2

.

2

2

.

5

.

1

5

0

.

1

8

7

.

1

5

.

8

3

.

0

3

.

9

.

1

2

3

.

1

8

9

.

4

6

.

8

4

.

8

3

.

Multipliers are based on drift of 0.02% of the circulating water rate

➠

maintenance