28

MPC-MLR-UM(A) 10/2009

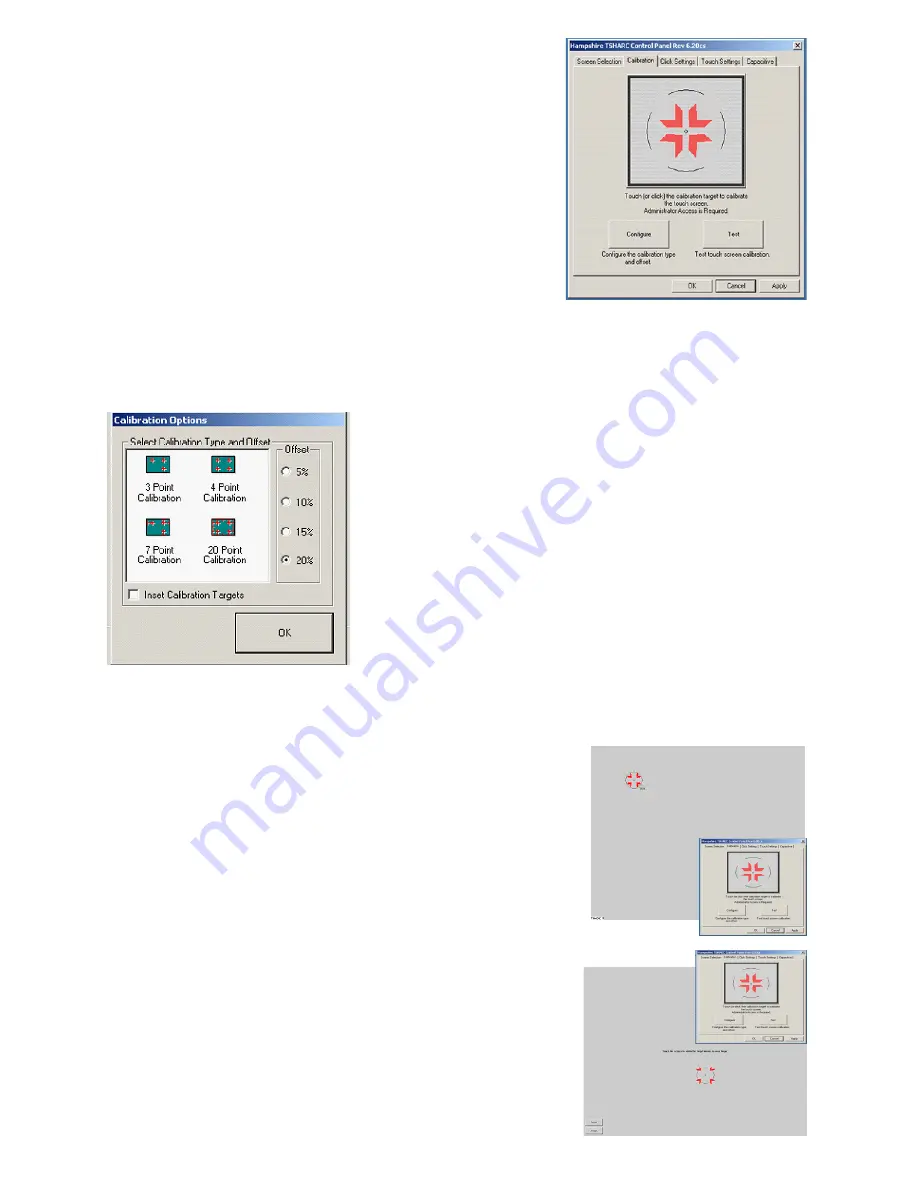

Calibration

The calibration process aligns the Touch Screen overlay

to specific points on the Display screen.

1. Select the Calibration tab or, in ten seconds, the

calibration program launches, unless a Multi-monitor

situation is present, then go to section Configuring a

Multi-monitor Installation

2. There are three buttons: Graphic, Calibration and

Test. For default Four-point calibration, select the

Graphic square. This is the best known general

calibration; it compensates for skew and some edge

linearity anomalies, and

3. Go to section Calibration Process.

Custom Calibration Settings

1. To customize the calibration process, select the Calibration button to bring up

Calibration Options and the Offset menu

2. Select OK when calibration and/or offset selections

are made:

• Three-Point Calibration: Quick calibration of a

known good Touch Screen overlay. No correc-

tion is applied

• Four-Point Calibration: Compensates for skew

and some edge linearity anomalies

• Seven-Point Calibration: More accurate than

three-point calibration. No correction is applied

• Twenty-Point Calibration: Provides the highest

level of Touch Screen linearization and skew cor-

rection, and

• Offset: Varied linearity exists between Touch

Screen types; user may want to calibrate the

edges of the Touch Screen more precisely.

Default is 20%.

Calibration Process

1. Press the Center Graphic to start calibration

2. Targets are used to calibrate the Touch Screen. Follow

the on-screen instructions - “Touch” the target center,

“hold” until it shrinks, then “release” the target, and

3. Repeat the process for all targets.

Note: the calibration screen shall time-out and return to the

Calibration tab if the first point is not touched within 10

seconds.

Calibration Verification Test

1. Touch the screen in several places to verify the

calibration target is displayed under the finger, and

2. Select the Accept button to apply and record the

calibration data.

Note: If the calibration target is not displayed under the finger,

select the Cancel button, repeat Custom Calibration Settings,

then Calibration Process.