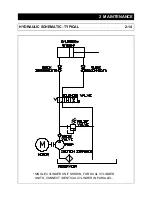

STANDARD SYSTEM OPERATING CHARACTERISTICS, 5 hp & 10 hp

The system uses special cylinders to move the ram and two timers to control the opera-

tion of the ram. When the hydraulic cylinders used in the RJ-88SC, RJ-100SC, RJ-

250SC, and RJ-250VL are fully extended or retracted, they bypass internally. This

makes it impossible for the hydraulic system to reach relief pressure. The sequence of

operation for this system is as follows:

Upon startup, a contact is made that energizes the motor starter, starting the electric

motor and at the same time energizing T1 timer coil. When T1 is energized, the valve

solenoid shifts the valve so that the hydraulic oil is directed to extend the cylinder which

extends the ram. When T1 timer times out, the contacts reverse causing T2 timer to

energize and the solenoid to shift the valve into the reverse position. In this position, the

valve directs the hydraulic oil into the front end of the cylinder causing the cylinder to

retract, therefore causing the ram to retract. When T2 timer times out, the motor starter

contact is opened causing the motor starter to shut down, therefore causing the

motor/power unit to shut down.

2 MAINTENANCE

PRINCIPLES OF OPERATION

2-6