www.mc-techgroup.com

MP30 | 1.00.01

15

14.1

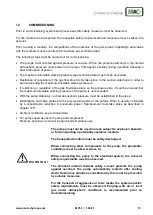

REPLACING DIAPHRAGMS, VALVE PLATES AND SEALING RINGS

Figure 4 shows a sectional drawing of the pump head.

1

2

3

4

5

6

7

8

9

10

11

15

Positioning

the cup

spring 11

Figure 3

Section drawing of pump head MP30

Replacing the diaphragm:

Mark position of pressure plate

15

, head cover

4

, intermediate plate

1

and housing

14

by making a

continuous line with a felt-tip pen.

Loosen four head screws

5.

Remove pressure plate

15

, head cover

4

and intermediate plate

1

from pump housing.

Loosen four fixing screws in impeller cover

13

and remove.

Bring diaphragm

8

into top position by turning impeller

12

;

Unscrew diaphragm on side edges anticlockwise.

1 Intermediate plate

2 Valve plate

3 Sealing ring

4 Head cover

5 Screw

6 Screw cap

7 Screw

8 Diaphragm

9 Supporting cup

10 Adjusting washers

11 Cup spring

12 Impeller

13 Impeller cover

14 Housing

15 Pressure plate

M Mark

15

14

13

12

1

4

5

6

M