Repairing coolant pump with high-temperature and

low-temperature parts D 2866 LUE 605

54

Replacing coolant pump during repair work only in event of identified leakage

The design of the coolant pump mechanical cassette seal permits small amounts of coolant to pass

through it.

This coolant passing through results in a trace of drained coolant below the drain bore.

This trace of drained coolant does not mean that the coolant pump has to be replaced.

For this reason, before replacing or repairing a coolant pump, ascertain

D

whether the cooling circuit shows visible and recurring signs of coolant loss; if yes

D

whether the coolant loss is caused by spillage from the expansion tank (e.g. too full) or by other leaka-

ges from hoses, radiator etc.

Coolant pumps may only then be replaced if dripping water can clearly be seen while the engine is running

or after it has been turned off.

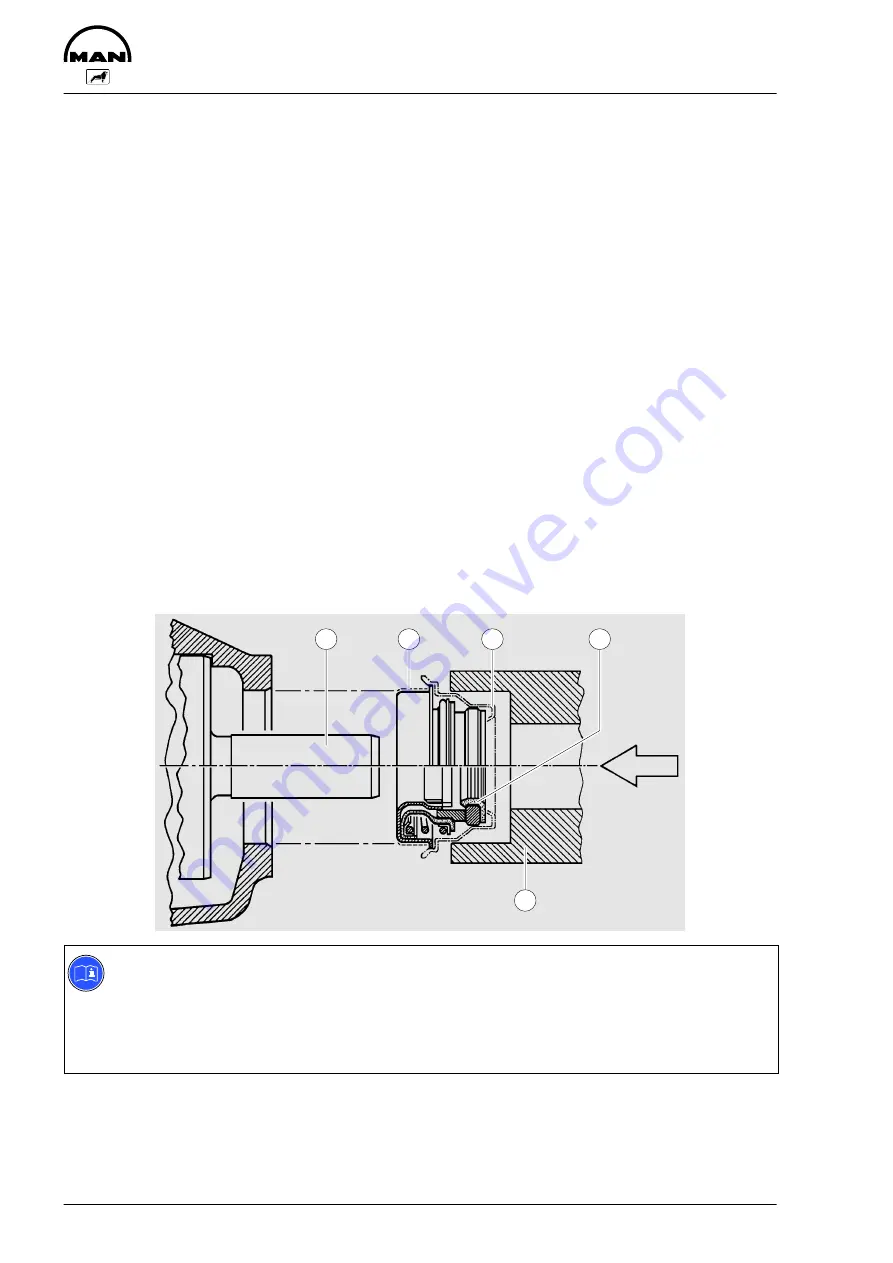

Installation note for mechanical seal:

Install mechanical seal while ”wet”, i.e. to install it, coat holding sleeve and water pump shaft with a mixture

of either 50% water and 50% cleaning spirit or 40% to 50% antifreeze agent as per MAN 324 and water.

Other antiseize agents must not be used.

Because the seal on collar

Á

is coated with sealing paint, no sealing paint needs to be applied if the loca-

ting bore in the coolant pump housing is in perfect condition.

If the bore shows even the slightest scoring or other minor damage, a sealing bead of Dirko-Transparent,

Part No. , must be applied to collar

Á

.

Fit the seal with a plastic transportation cap onto shaft

À

and use installation tool Ä to press it in until the

tool contacts the housing. Remove the plastic cap.

1

2

3

4

5

Note:

Tests have shown that most cases of damage to the coolant pump can be attributed to the use of

unsuitable coolants.

Only

the anticorrosion and antifreeze agents expressly approved by MAN Nutzfahrzeuge AG as

per MAN norm 324 (see brochure “Fuels, Lubricants, Coolants for and MAN Diesel Engines”)

guarantee faultless operation

Содержание D 2866 LUE 605

Страница 1: ......

Страница 2: ......

Страница 14: ...Notes 12...

Страница 19: ...Memoranda 17...

Страница 20: ...Engine views 18 Engine views 3 4 2 1 7 6 5 8 11 10 9...

Страница 68: ...Memoranda 66...

Страница 133: ...131 Service Data...

Страница 157: ...155 Special tools...

Страница 158: ...Special tools 156 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Страница 160: ...Special tools 158 10 11 16 14 14 1 12 13 18 18 1 12 1 12 2 15 5 15 4 15 1 15 1 15 2 15 3 15 3 15 6 15 7 15 17...

Страница 162: ...Special tools 160 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 23 28...

Страница 164: ...Special tools 162 30 31 32 1 32 32 2...

Страница 167: ...Special tools 165 Pressing mandel for cap dia 62 1 mm Pressing mandel for cap dia 50 1 mm...

Страница 170: ...Notes 168...

Страница 173: ......

Страница 174: ......