1R165

Large spiral bevel gear

P

6

/

8

R

epair

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Large spiral bevel gear, Ball bearing 608ZZ, Ball bearing 6202DDW (cont.)

DISASSEMBLING

ASSEMBLING

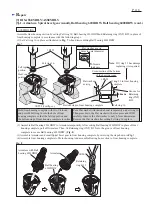

(2) Ball bearing 6202DDW can be disassembled as illustrated in

Fig. 12A

or

Fig. 12B

.

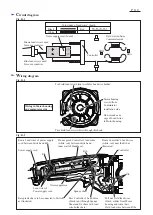

Reverse the disassembling step shown in Fig. 11, 10R and 9.

Note

: 1) Do not deform the labyrinth ring of Spindle complete when pressfitting Spindle complete to Ball bearing

6202DDW. (

Fig. 13

)

2) Putting Large spiral bevel gear on 1R165, press Spindle into arbor hole of Large spiral bevel gear with Arbor

press. (

Fig. 14

)

Fig. 12A

Fig. 12B

Fig. 13

If it is difficult to remove as illustrated

in

Fig. 13A

, remove Ball bearing

6202DDW with the appropriate

diameter round bar and Arbor press.

Remove Ball bearing 6202DDW by striking Bearing box

against Work table.

Ball bearing

6202DDW

Bearing box

Round bar

Ball bearing 6202DDW

Labyrinth ring

of Spindle complete

Fig.14