15 ENGLISH

1

►

1.

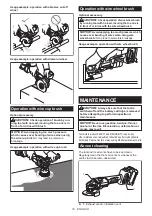

Wire wheel brush

Remove the battery cartridge from the tool and place it

upside down allowing easy access to spindle.

Remove any accessories on spindle. Thread wire wheel

brush onto spindle and tighten with the wrenches.

OPERATION

WARNING:

It should never be necessary to

force the tool.

The weight of the tool applies ade-

quate pressure. Forcing and excessive pressure

could cause dangerous wheel breakage.

WARNING:

ALWAYS replace wheel if tool is

dropped while grinding.

WARNING:

NEVER bang or hit grinding disc

or wheel onto work.

WARNING:

Avoid bouncing and snagging

the wheel, especially when working corners,

sharp edges etc.

This can cause loss of control and

kickback.

WARNING:

NEVER use tool with wood cutting

blades and other saw blades.

Such blades when

used on a grinder frequently kick and cause loss of

control leading to personal injury.

CAUTION:

Never switch on the tool when it

is in contact with the workpiece, it may cause an

injury to operator.

CAUTION:

Always wear safety goggles or a

face shield during operation.

CAUTION:

After operation, always switch off

the tool and wait until the wheel has come to a

complete stop before putting the tool down.

CAUTION:

ALWAYS hold the tool firmly with

one hand on housing and the other on the side

grip (handle).

Grinding and sanding operation

Turn the tool on and then apply the wheel or disc to the

workpiece.

In general, keep the edge of the wheel or disc at an

angle of about 15° to the workpiece surface.

During the break-in period with a new wheel, do not

work the grinder in forward direction or it may cut into

the workpiece. Once the edge of the wheel has been

rounded off by use, the wheel may be worked in both

forward and backward direction.

Operation with abrasive cut-off /

diamond wheel

Optional accessory

WARNING:

Do not "jam" the wheel or apply

excessive pressure. Do not attempt to make an

excessive depth of cut.

Overstressing the wheel

increases the loading and susceptibility to twisting

or binding of the wheel in the cut and the possibility

of kickback, wheel breakage and overheating of the

motor may occur.

WARNING:

Do not start the cutting operation

in the workpiece. Let the wheel reach full speed

and carefully enter into the cut moving the tool

forward over the workpiece surface.

The wheel

may bind, walk up or kickback if the power tool is

started in the workpiece.

WARNING:

During cutting operations, never

change the angle of the wheel.

Placing side pres-

sure on the cut-off wheel (as in grinding) will cause

the wheel to crack and break, causing serious per-

sonal injury.

WARNING:

A diamond wheel shall be oper-

ated perpendicular to the material being cut.

Содержание GA007G

Страница 19: ...19 ...