31

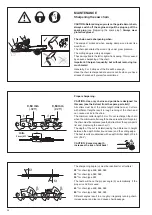

Trouble shooting

Malfunction

System

Observation

Cause

Chain does not run

Chain brake

Engine runs

Chain brake actuated.

Engine does not start or

Ignition system

Ignition spark

Malfunction in fuel supply system, com‑

only with difficulty

pression system, mechanical malfunction.

No ignition spark

STOP switch actuated,

fault or short‑circuit in

Spark plug cap or spark plug defective

t

Fuel supply

Fuel tank is filled

Combination switch in Choke position,

carburetor defective, suction head dirty, fuel

line bent or interrupted.

Compression

Inside

Cylinder base packing ring defective, radial

system

shaft packings defective, cylinder or piston

rings defective

Outside

Spark plug does not seal.

Mechanical

Starter does not engage

Spring in starter broken, broken parts

malfunction

inside the engine.

Warm start difficulties

Carburetor

Fuel tank is filled

Wrong carburetor adjustment.

Ignition spark

Engine starts, but

Fuel supply

Fuel tank is filled

Wrong idling adjustment, suction head or

dies immediately

carburetor dirty.

Tank venting defective, fuel line interrupted,

cable defective, Combination switch defective.

Insufficient power

Several systems

Engine is idling

Air filter dirty, wrong carburetor adjustment,

may be involved

muffler clogged, exhaust channel in cylinder

simultaneously

clogged, spark arrester screen clogged.

No chain lubrication

Oil tank/pump

No oil on the chain

Oil tank empty.

Oil guide groove dirty.

Oil‑pump adjusting screw incorrectly adjusted.

Содержание EA5600F

Страница 35: ...35...