9 ENGLISH

Example of application

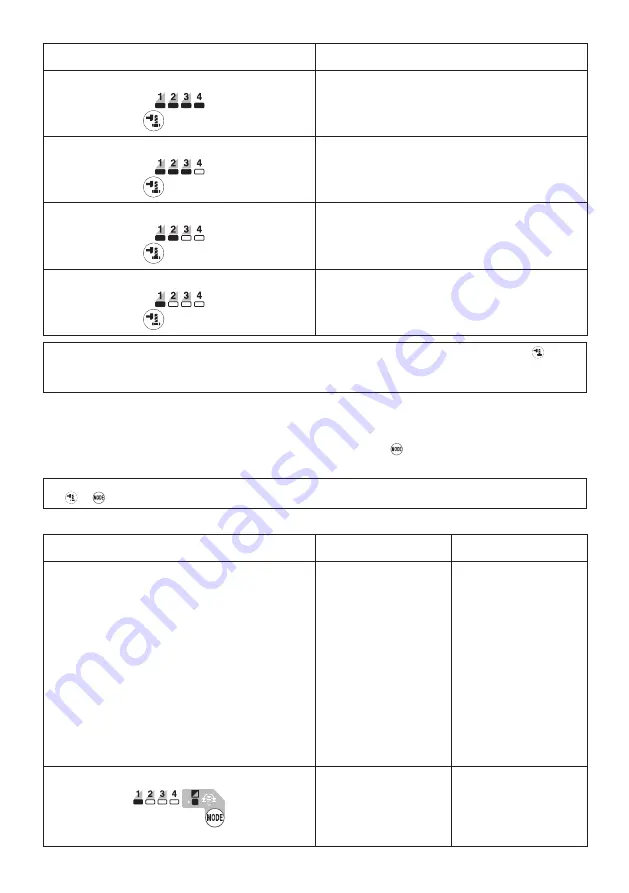

Application mode

(Impact force grade displayed on panel)

Example of application

4 (Max)

Assembling steel frames and tightening long screws or bolts.

3 (Hard)

Assembling steel frames.

2 (Medium)

Assembling or disassembling scaffolds and frameworks.

1 (Soft)

Assembling furniture.

NOTE:

When none of the lamp on the panel is lit, pull the switch trigger once before pressing the button .

NOTE:

All lamps on the switch panel go out when the tool is turned off to save the battery power. The impact force

grade can be checked by pulling the switch trigger to the extent that the tool does not operate.

Changing the application mode

This tool employs several easy-to-use application modes for driving bolts with good control.

The type of the application mode changes every time you press the button

.

You can change the application mode within approximately one minute after releasing the switch trigger.

NOTE:

You can extend the time to change the application mode approximately one minute if you press the but

-

ton or .

►

Fig.8

Application mode

(Assist type displayed on panel)

Feature

Purpose

Bolt mode

Clockwise

This mode helps to repeat screw-

driving continuously with equal

torque. This mode also helps to

reduce the risk of breakage of

bolts/nuts due to overtightening.

Counterclockwise

This mode helps to prevent a bolt

from falling off. When loosening a

bolt with the tool driving in counter-

clockwise rotation, the tool auto-

matically stops or slows down after

the bolt/nut gets enough loosened.

NOTE:

The timing to stop the driving

varies depending on the type

of the bolt/nut and material to

be driven. Make a test driving

before using this mode.

Clockwise

Preventing overtightening of

bolts.

Counterclockwise

Loosening bolts.

Bolt mode (1)

Clockwise

The tool stops automatically as

soon as it has started impact blows.

Counterclockwise

The impact force is 4. The tool

stops automatically as soon as

it has stopped impact blows.

–