12 ENGLISH

Quick mode-switching function

What you can do with the quick mode-

switching function

The quick mode-switching function saves the time for changing

the application mode of the tool. You can switch to your desired

application mode by just pressing the quick mode-switching

button. It is helpful when doing a repetitive work which requires

to switch between two application modes alternately.

EXAMPLE

If you have a work to use T mode and max

impact force, register the max impact force for quick

mode-switching function. Once register it, you can switch

to the max impact force from T mode by just one click of

the quick mode-switching button. Also, you can return to T

mode by pressing the quick mode-switching button again.

Even if the tool is in other application mode than T

mode, pressing the quick mode-switching button

changes to max impact force. It is convenient for you

to register a application mode that you frequently use.

You can choose one of following application modes for

quick mode-switching function:

Impact force

• Max

• Hard

• Medium

• Soft

Assist type

•

Wood mode

•

Bolt mode

•

T mode (1)

•

T mode (2)

Registering application mode

To use the quick mode-switching function, register your

desired application mode to the tool beforehand.

1.

With the button

or

, choose your desired

application mode.

2.

Press and hold the button

and the quick

mode-switching button at the same time until the custom-

ize lamp and the lamp of desired application mode blinks.

1

2

►

1.

Quick mode-switching button

2.

Customize lamp

NOTE:

You can overwrite the current application mode

with new one by performing the procedure above.

Using the quick mode-switching function

When the tool is in the mode that is not registered,

press the quick mode-switching button to switch to the

registered application mode. The tool switches between

the registered application mode and last application

mode every time you press the quick mode-switching

button. The front lamps on both sides will flash once

when switching to the registered application mode.

NOTE:

The customize lamp will light up when the

application mode registered to the tool is chose.

Cancelling the quick mode-switching

function

Press and hold the button

and quick mode-switch-

ing button at the same time until the customize lamp

and all impact force grade lamps blink.

NOTE:

After cancelling the quick mode-switching

function, the quick mode-switching button works for

changing the impact force.

ASSEMBLY

CAUTION:

Always be sure that the tool is

switched off and the battery cartridge is removed

before carrying out any work on the tool.

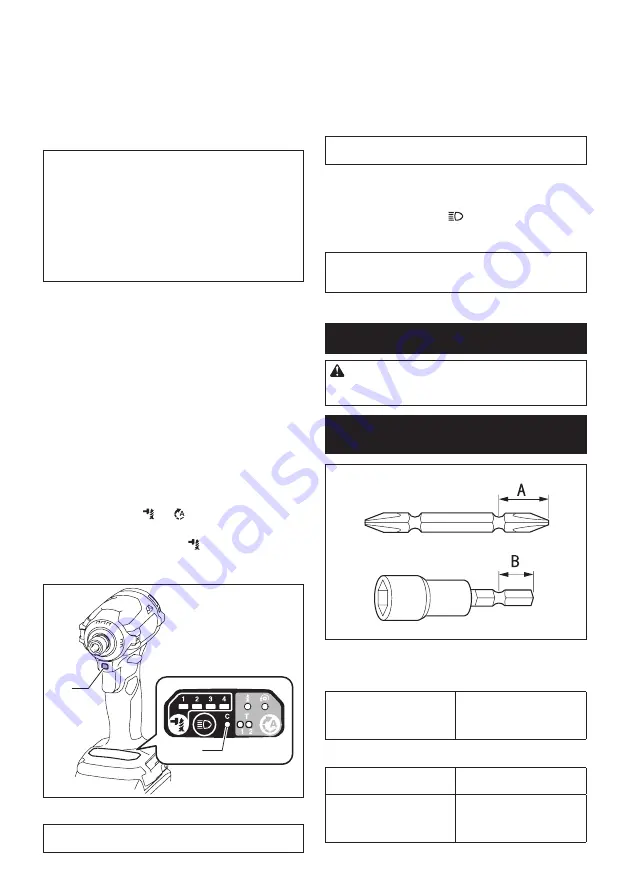

Installing or removing driver bit/

socket bit

Use only driver bit/socket bit that has inserting portion shown

in the figure. Do not use any other driver bit/socket bit.

For tool with shallow driver bit hole

A=12mm

B=9mm

Use only these type of driver

bit. Follow the procedure

1. (Note) Bit-piece is not

necessary.

For tool with deep driver bit hole

A=17mm

B=14mm

To install these types of driver

bits, follow the procedure 1.

A=12mm

B=9mm

To install these types of driver

bits, follow the procedure 2.

(Note) Bit-piece is necessary

for installing the bit.