9

ENGLISH

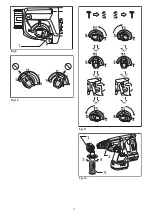

Place the quick change drill chuck on the spindle of

the tool.

Grasp the change cover of the quick change drill chuck

and turn the change cover line to the

symbol until a

click can clearly be heard.

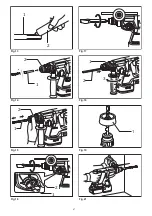

Selecting the action mode

Rotation with hammering

►

Fig.7:

1.

Rotation with hammering

2.

Lock button

3.

Action mode changing knob

For drilling in concrete, masonry, etc., depress the lock

button and rotate the action mode changing knob to

the

symbol. Use a tungsten-carbide tipped bit.

Rotation only

►

Fig.8:

1.

Rotation only

For drilling in wood, metal or plastic materials, depress

the lock button and rotate the action mode changing

knob to the

symbol. Use a twist drill bit or wood bit.

Hammering only

►

Fig.9:

1.

Hammering only

For chipping, scaling or demolition operations, depress

the lock button and rotate the action mode changing

knob to the

symbol. Use a bull point, cold chisel,

scaling chisel, etc.

Notice on the action mode changing

knob operation

To avoid the damage to the mechanism of the action

mode changing knob, follow the procedures below:

•

Do not rotate the action mode changing knob

when the tool is running.

•

Make sure that the action mode changing knob is

always positively located in one of the three action

mode positions (

,

, or

).

►

Fig.10

•

Do not turn the knob forcibly. Forcing the knob

may cause tool damage.

When turning the action mode changing knob from

the

symbol to the

symbol or vise versa, the

knob may no longer move in the

symbol posi

-

tion. In this case, move the knob to the

symbol

position and run the tool few seconds. After that,

move the knob to the desired position.

►

Fig.11

Torque limiter

The torque limiter will actuate when a certain torque

level is reached. The motor will disengage from the out

-

put shaft. When this happens, the bit will stop turning.

CAUTION:

•

As soon as the torque limiter actuates, switch

off the tool immediately. This will help prevent

premature wear of the tool.

•

Hole saws cannot be used with this tool. They

tend to pinch or catch easily in the hole. This will

cause the torque limiter to actuate too frequently.

ASSEMBLY

CAUTION:

•

Always be sure that the tool is switched off and

the battery cartridge is removed before carrying

out any work on the tool.

Side grip (auxiliary handle)

►

Fig.12:

1.

Protrusion

2.

Groove

3.

Loosen

4.

Tighten

5.

Side grip

CAUTION:

•

Always use the side grip to ensure operating

safety.

Install the side grip so that the protrusion on the grip fit

in between the grooves in the tool barrel. Then tighten

the grip by turning clockwise at the desired position. It

may be swung 360° so as to be secured at any position.

Bit grease

Coat the bit shank head beforehand with a small

amount of bit grease (about 0.5 -1 g). This chuck lubri

-

cation assures smooth action and longer service life.

Installing or removing the bit

Clean the bit shank and apply bit grease before install

-

ing the bit.

►

Fig.13:

1.

Bit shank

2.

Bit grease

Insert the bit into the tool. Turn the bit and push it in until

it engages.

►

Fig.14:

1.

Bit

2.

Chuck cover

If the bit cannot be pushed in, remove the bit. Pull the

chuck cover down a couple of times. Then insert the bit

again. Turn the bit and push it in until it engages.

After installing, always make sure that the bit is securely

held in place by trying to pull it out.

To remove the bit, pull the chuck cover down all the way

and pull the bit out.

►

Fig.15:

1.

Bit

2.

Chuck cover

Bit angle (when chipping, scaling or

demolishing)

►

Fig.16:

1.

Action mode changing knob

2.

O symbol

The bit can be secured at the desired angle. To change

the bit angle, depress the lock button and rotate the

action mode changing knob to the

O

symbol. Turn the

bit to the desired angle.

Depress the lock button and rotate the action mode

changing knob to the

symbol. Then make sure that

the bit is securely held in place by turning it slightly.

►

Fig.17

Depth gauge

►

Fig.18:

1.

Hole

2.

Depth gauge

3.

Loosen

4.

Tighten

The depth gauge is convenient for drilling holes of

uniform depth. Loosen the side grip and insert the depth

gauge into the hole in the side grip. Adjust the depth

gauge to the desired depth and tighten the side grip.

Содержание DHR243Z

Страница 2: ...1 2 3 1 1 1 A B 1 2 3 1 2 3 4 1 2 3 1 Fig 1 Fig 2 Fig 3 Fig 4 Fig 5 Fig 6 Fig 7 Fig 8 2 ...

Страница 3: ...1 Fig 11 1 2 3 4 5 Fig 9 Fig 10 Fig 12 3 ...

Страница 4: ...1 2 2 1 1 2 1 2 1 2 3 4 1 Fig 13 Fig 14 Fig 15 Fig 16 Fig 17 Fig 18 Fig 19 Fig 21 4 ...

Страница 5: ...1 1 2 1 2 1 2 3 1 2 3 4 1 2 3 Fig 22 Fig 23 Fig 24 Fig 25 Fig 26 Fig 27 Fig 28 5 ...