[3]-1 Impact Assembly, Anvil

Pin guide

with Pin 1.2-3.5

Pin guide

with Pin 1.2-3.5

ASSEMBLING

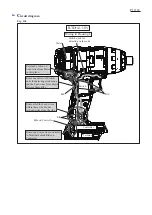

(3) Assemble Change case, Change sleeve, Pin guides with Pin 1.2-3.5, Compression spring 2 and Hammer change ring

to Gear case assembly (

Fig. 11

,

Fig. 12

).

Fig. 12

Fig. 11

Notch for Speed change

lever

Tail of Change case

1. Assemble Change case while locating its Tail

to the opposite side of Notch for Speed change

lever.

2. Insert Change sleeve into Gear case assembly while facing

the groove of Change sleeve to motor side.

Note:

Make sure to assemble Change sleeve in the correct

direction (the groove is faced to motor side) so as to fit

Pin 1.2-3.5 to the groove of Change sleeve in the next step.

Change case

Elliptical hole

1. Align the elliptical hole of Change case to that of

Gear case assembly by turning Change case.

The groove of Change sleeve is seen through the elliptical holes

of Change case and Gear case assembly.

Elliptical hole

Groove of

Change sleeve

Change sleeve

Change sleeve

Groove of Change sleeve

Change case

3. Mount 2 pcs of Compression spring 2 to

Gear case assembly and assemble Hammer

change ring to Gear case assembly by fitting

its two holes to the Compression springs.

Gear case

assembly

Groove of

Change sleeve

2. Apply grease to the elliptical holes of

Change case so that the Pin guide sticks

on the elliptical holes of Change case.

Mount Pin guide with Pin 1.2-3.5 to

the groove of Change sleeve.

Hammer change ring

Compression

spring 2

(4) Assemble Hammer change plates while pressing Hammer change ring with your fingers at its two points.

Refer to

Fig. 6

.

NG

R

epair

P

9

/

18