P 1

2

/

18

R

epair

[3]-1 Impact Assembly, Anvil

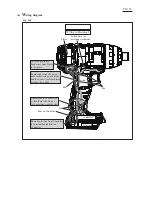

ASSEMBLING

(8) Assemble Speed change lever to Impact assembly (

Fig. 16

).

(9) Now, Impact assembly is assembled completely. And assemble Motor section (Rotor and Stator complete)

to the Impact assembly (

Fig. 4

-3

).

Mount 2 pcs. of Switch unit to Motor bracket assembly and set the Impact assembly together with Motor section to

Housing L (

Fig. 4

-2

).

(10) Assemble F/R Change lever to Switch, and mount Switch plate complete to Housing L (

Fig. 17

).

Fig. 16

Fig. 17

1. Insert 2 pcs of Compression spring 3

to Speed change lever assembly.

2. Mount Speed change lever assembly by fitting

the space between two Compression springs to

the projection of Change lever.

Put end of Spring in this

frame.

Compression spring 3

Projection of

Change lever

(11) Tighten Hammer case assembly with Socket 32-50, 1R223 and 1R224 (

Fig. 3

).

Note; The fastening torque for Hammer case assembly is

15 - 20 N.m

.

F/R Change lever

Switch

3. Facing the symbols of “Job light” and

“Battery power display” to front side,

set Switch plate complete to Housing L.

1. Fit the projection of Switch to

fork portion of F/R change lever.

2. Set the Switch with F/R change lever

to Housing L.

Projection

of Switch

Prong of

F/R Change lever

Battery power

display

Job light