4

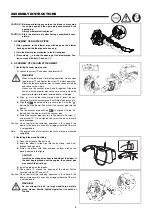

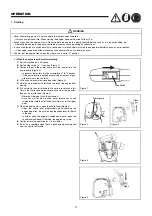

Start the Blower only in accordance with the instructions.

Do not use any other methods for starting the engine (6) !

• Use the blower and the tools supplied only for applications specified.

• Start the blower engine only after the entire tool has been assembled.

Operation of the tool is permitted only after all the appropriate acces-

sories are attached.

• The engine is to be switched off immediately if there are any engine

problems.

• When working with the blower, always wrap your fingers tightly around

the handle, keeping the control handle cradled between your thumb

and forefinger. Keep your hand in this position to have your machine

under control at all times. Make sure your control handle (and grip for

vacuum attachment) are in good condition and free of moisture, pitch,

oil or grease.

Always ensure a safe, well-balanced footing.

• Operate the blower in such a manner as to avoid inhalation of the

exhaust gases. Never run the engine in enclosed rooms (risk of suffo-

cation and gas poisoning). Carbon monoxide is an odorless gas.

Always ensure there is adequate ventilation.

• Switch off the engine when resting and when leaving the blower unat-

tended. Place it in a safe location prevent danger to others, setting fire

to combustible materials, or damage to the machine.

• Never lay the hot blower onto dry grass or onto any combustible mate-

rials.

• All protective parts and guards supplied with the machine must be

used during operation.

• Never operate the engine with a faulty exhaust muffler.

• Shut off the engine during transport (7).

• Position the blower safely during car or truck transportation to avoid

fuel leakage.

• When transporting the blower, ensure that the fuel tank is completely

empty.

Refuelling

• Shut off the engine during refuelling (7), keep well away from open

flame (8) and do not smoke.

• Avoid skin contact with petroleum products. Do not inhale fuel vapor.

Always wear protective gloves during refuelling. Change and clean

protective clothing at regular intervals.

• Take care not to spill either fuel or oil in order to prevent soil contamina-

tion (environmental protection). Clean the blower immediately after fuel

has been spilt. Allow wet cloths to dry before disposing in properly,

covered container to prevent spontaneous combustion.

• Avoid any fuel contact with your clothing. Change your clothing imme-

diately if fuel has been spilled on it (fire hazard).

• Inspect the fuel cap at regular intervals making sure that it stays

securely fastened.

• Carefully tighten the locking screw of the fuel tank. Change locations to

start the engine (at least 3 meters away from the place of refuelling)

(9).

• Never refuel in closed rooms. Fuel vapors accumulate at ground level

(risk of explosions)

• Only transport and store fuel in approved containers. Make sure stored

fuel is not accessible to children.

• Do not attempt to refuel a hot or a running engine.

(6)

(7)

(8)

(9)

3 meters

• Resting

• Transport

• Refuelling

• Maintenance

• Tool Replacement

Содержание BHX2500V

Страница 19: ...19 MEMO ...

Страница 20: ...Makita Corporation Anjo Aichi Japan www makita com 884857E889 IDE ...