7 - 52

7.9

Axis Covers and Chip Scraper Unit

The machine is equipped with numerous sheet metal covers enclosing the

machining area to contain coolant, chips, and machine surfaces. A major-

ity of the covers are stationary and do not require removal for mainte-

nance procedures. This section discusses the X axis Roll-up, Y axis guide

way, and ball screw covers which may require removal.

7.9.1

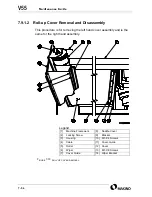

X Axis Roll-up Cover

The X axis roll-up cover consists of two roll-up cover assemblies (on each

side of machine) mounted to frame work above the machining area with

the free end of each cover attached to the saddle. As the X axis moves

(plus or minus) one cover extends while the other rolls up. Roll-up is

accomplished by spring loading the mechanism. A tensioning device is

used to maintain proper cover tension on the roll-up mechanisms.

7.9.1.1

Roll-up Cover Tensioning

The roll-up cover tensioning mechanism consists of:

•

Two wire cables, one for each roller

•

Adjustable, spring loaded, tensioner with cleaves type ends for cable

attachment

One wire cable is attached to each roller. The cables wrap several times

around one end of each roller with the free ends connected by cleaves on

both ends of the tensioner.

Attaching the Tensioning Cables:

If installing new or re-wrapping cables:

1. Make an equal number of cable wraps around each roller.

2. Check the position where the cable ends meet. They should extend

approximately equal distances from each roller and far enough to allow

the tensioning device to be connected.

3. Connect the cable ends to the cleaves on both ends of the tensioner.

Содержание V55

Страница 6: ...vi...

Страница 32: ...1 24 NOTES SKETCHES...

Страница 37: ...4V2A1563 E 2 3 FIGURE 2 1 SPINDLE POWER AND TORQUE CHARACTERISTICS...

Страница 39: ...4V2A1563 E 2 5 FIGURE 2 2 AXIS CONFIGURATION TRAVEL AND WORK CUBE...

Страница 41: ...4V2A1563 E 2 7 FIGURE 2 4 WORKPIECE SIZE LIMITATIONS...

Страница 53: ...4V2A1563 E 2 19 FIGURE 2 6 FLOOR SPACE FOR STANDARD MACHINE...

Страница 58: ...2 24 F IGURE 2 7 V55 WITH 25 TOOL ATC...

Страница 59: ...4V2A1563 E 2 25 F IGURE 2 8 V55 WITH 25 TOOL ATC AND LIFT UP CHIP CONVEYOR LEFT...

Страница 60: ...2 26 F IGURE 2 9 V55 WITH 25 TOOL ATC AND LIFT UP CHIP CONVEYOR RIGHT...

Страница 61: ...4V2A1563 E 2 27 F IGURE 2 10 V55 WITH 25 TOOL ATC LIFT UP CHIP CONVEYOR LEFT AND APC...

Страница 62: ...2 28 F IGURE 2 11 V55 WITH 25 TOOL ATC LIFT UP CHIP CONVEYOR RIGHT AND APC...

Страница 63: ...4V2A1563 E 2 29 F IGURE 2 12 V55 WITH 40 OR 80 TOOL ATC...

Страница 64: ...2 30 F IGURE 2 13 V55 WITH 40 OR 80 TOOL ATC AND LIFT UP CHIP CONVEYOR LEFT...

Страница 65: ...4V2A1563 E 2 31 F IGURE 2 14 V55 WITH 40 OR 80 TOOL ATC AND LIFT UP CHIP CONVEYOR RIGHT...

Страница 66: ...2 32 F IGURE 2 15 V55 WITH 40 OR 80 TOOL ATC LIFT UP CHIP CONVEYOR LEFT AND APC...

Страница 67: ...4V2A1563 E 2 33 F IGURE 2 16 V55 WITH 40 OR 80 TOOL ATC LIFT UP CHIP CONVEYOR RIGHT AND APC...

Страница 68: ...2 34 NOTES SKETCHES...

Страница 93: ...4V2A1563 E 3 23 FIGURE 3 6 LEVELING BASE POSITIONS AND BED TO FLOOR CLEARANCE...

Страница 94: ...3 24 NOTES SKETCHES...

Страница 99: ...4V2A1563 E 4 3 FIGURE 4 1 MACHINE CORE ELEMENTS...

Страница 103: ...4V2A1563 E 4 7 FIGURE 4 3 MAKINO PROFESSIONAL 3 CONTROL WITH MPC5...

Страница 106: ...4 10 NOTES SKETCHES...

Страница 114: ...4 18 NOTES SKETCHES...

Страница 123: ...4V2A1563 E 5 5 FIGURE 5 1 BASIC TROUBLESHOOTING FLOW CHART...

Страница 124: ...5 6 NOTES SKETCHES...

Страница 143: ...4V2A1563 E 5 25 NOTES SKETCHES...

Страница 153: ...4V2A1563 E 5 35 NOTES SKETCHES...

Страница 159: ...4V2A1563 E 5 41 NOTES SKETCHES...

Страница 166: ...5 48 NOTES SKETCHES...

Страница 191: ...4V2A1563 E 5 73 TEC F IGURE 5 26 S CHEMATIC PAGE FORMAT...

Страница 197: ...4V2A1563 E 5 79 NOTES SKETCHES...

Страница 198: ...5 80 NOTES SKETCHES...

Страница 202: ...NOTES SKETCHES...

Страница 227: ...4V2A1563 E 6 25 NOTES SKETCHES...

Страница 252: ...6 50 NOTES SKETCHES...

Страница 261: ...4V2A1563 E 6 59 FIGURE 6 36 SPINDLE HYDRAULIC CIRCUIT...

Страница 267: ...4V2A1563 E 6 65 FIGURE 6 40 L PORT SPINDLE LUBRICATION...

Страница 269: ...4V2A1563 E 6 67 FIGURE 6 41 V PORT SPINDLE LUBRICATION...

Страница 277: ...4V2A1563 E 6 75 NOTES SKETCHES...

Страница 279: ...4V2A1563 E 6 77 FIGURE 6 48 SEALING ROD INSTALLATION...

Страница 284: ...6 82 NOTES SKETCHES...

Страница 293: ...4V2A1563 E 7 5 F IGURE 7 3 AXIS DRIVE CIRCUIT...

Страница 297: ...4V2A1563 E 7 9 NOTES SKETCHES...

Страница 309: ...4V2A1563 E 7 21 FIGURE 7 12 BALL SCREW COOLING OIL AND TAC BEARING LUBRICATION PIPING...

Страница 311: ...4V2A1563 E 7 23 NOTES SKETCHES...

Страница 317: ...4V2A1563 E 7 29 FIGURE 7 18 BALL SCREW PRE TENSION PROCEDURE...

Страница 331: ...4V2A1563 E 7 43 FIGURE 7 26 Y AXIS LIMIT SWITCH TO DOG SETTINGS FIGURE 7 27 Z AXIS LIMIT SWITCH TO DOG SETTINGS...

Страница 346: ...7 58 NOTES SKETCHES...

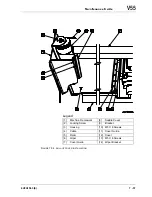

Страница 348: ...7 60 FIGURE 7 35 Y AXIS COVER SYSTEM...

Страница 351: ...4V2A1563 E 7 63 NOTES SKETCHES...

Страница 369: ...4V2A1563 E 7 81 NOTES SKETCHES...

Страница 370: ...7 82 NOTES SKETCHES...

Страница 374: ...NOTES SKETCHES...

Страница 386: ...8 12 NOTES SKETCHES...

Страница 403: ...4V2A1563 E 8 29 NOTES SKETCHES...

Страница 423: ...4V2A1563 E 8 49 NOTES SKETCHES...

Страница 432: ...8 58 NOTES SKETCHES...

Страница 439: ...4V2A1563 E 9 5 NOTES SKETCHES...

Страница 441: ...4V2A1563 E 9 7 F IGURE 9 3 OIL CONTROLLER ELECTRICAL DRAWINGS...

Страница 443: ...4V2A1563 E 9 9 FIGURE 9 4 OIL CONTROLLER MACHINE SYSTEM...

Страница 464: ...9 30 NOTES SKETCHES...

Страница 468: ...NOTES SKETCHES...

Страница 490: ...A 22 NOTES SKETCHES...

Страница 525: ...4V2A1563 E A 57 NOTES SKETCHES...

Страница 526: ...A 58 NOTES SKETCHES...

Страница 534: ...B 6 NOTES SKETCHES...

Страница 546: ...B 18 NOTES SKETCHES...

Страница 558: ...B 30 NOTES SKETCHES...

Страница 564: ...B 36 NOTES SKETCHES...

Страница 568: ...B 40 NOTES SKETCHES...