20

BA363901-en

Pos: 88 / Technische Dokumentation/Alle Geräte/Überschriften/ Überschriften 1.1/SCH/Überschrift 1.1: Schmierstellen @ 14\mod_ 1241506822762_ 75.docx @ 370057 @ 2 @ 1

6.5

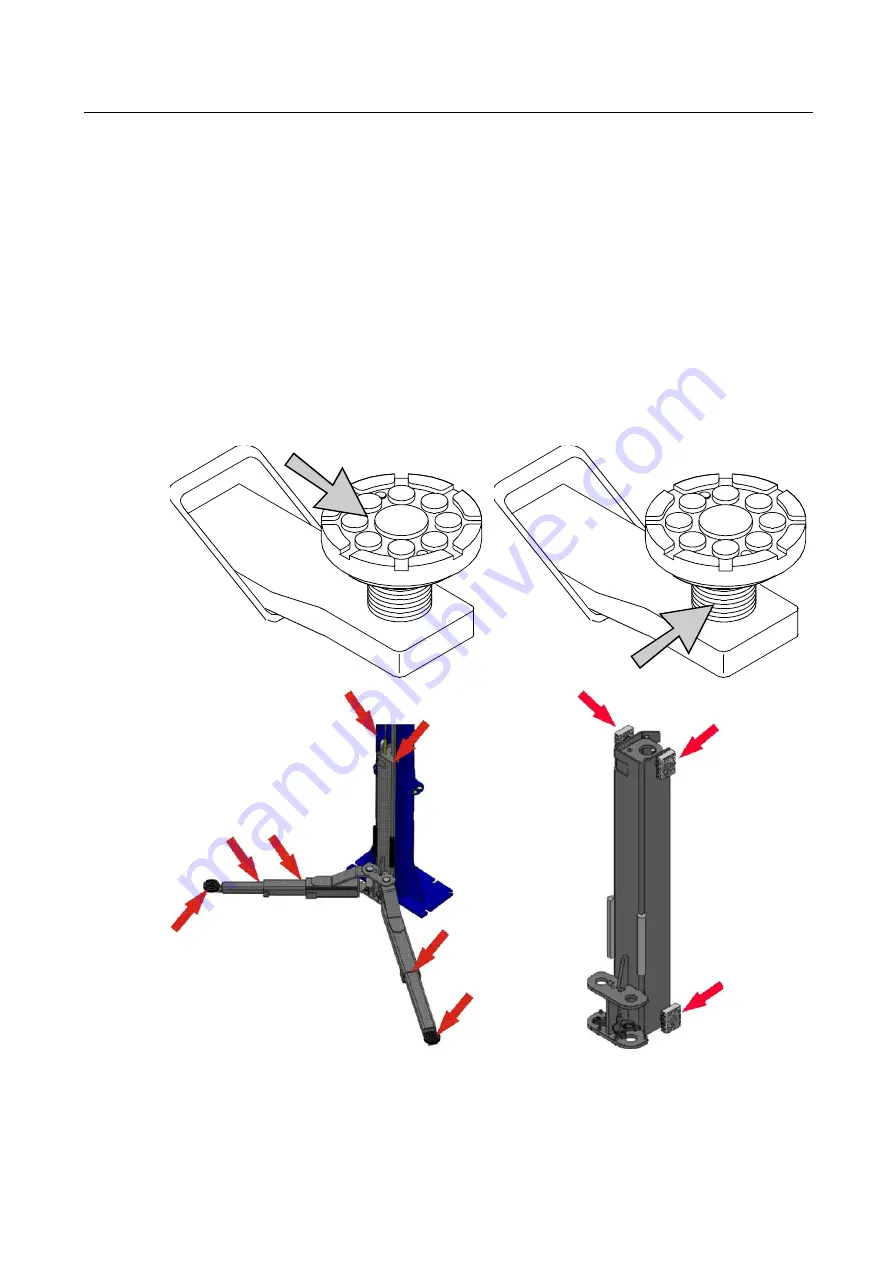

Greasing Points

Pos: 89 / Technische Dokumentation/Hebetechnik/- Archiv -/ 36 Säulen-Hebebühnen/ 3901 HL CS 4.0/ BA/Inhalt: 3639 Schm ierstellen (Text) @ 29\mod_ 1350639396740_75.d ocx @ 1665951 @ @ 1

•

The slide tracks must be greased every six months or as required (e. g. in case

of noise generation). Slightly grease the tracks over their whole length using a

brush.

•

Every six months check support arm extensions for smooth operation. Grease

as required.

•

Every six months check threads of disc adapters for smooth operation. Grease

as required.

•

Weekly check the rubber pads for wear. Replace as required.

•

Grease the slider blocks at the rear bracket of the carriages.

Pos: 90 / Technische Dokumentation/Hebetechnik/- Archiv -/ 36 Säulen-Hebebühnen/ 3901 HL CS 4.0/ BA/Inhalt: 3639 Schm ierstellen (Bild er) @ 29\mod_ 1347614535366_ 0.d ocx @ 1653893 @ @ 1

Pos: 91 /----- Format-----/MAN UELLER UM BRUCH Seitenumbruch @ 0\m od_1134403577687_ 0.docx @ 1277 @ @ 1