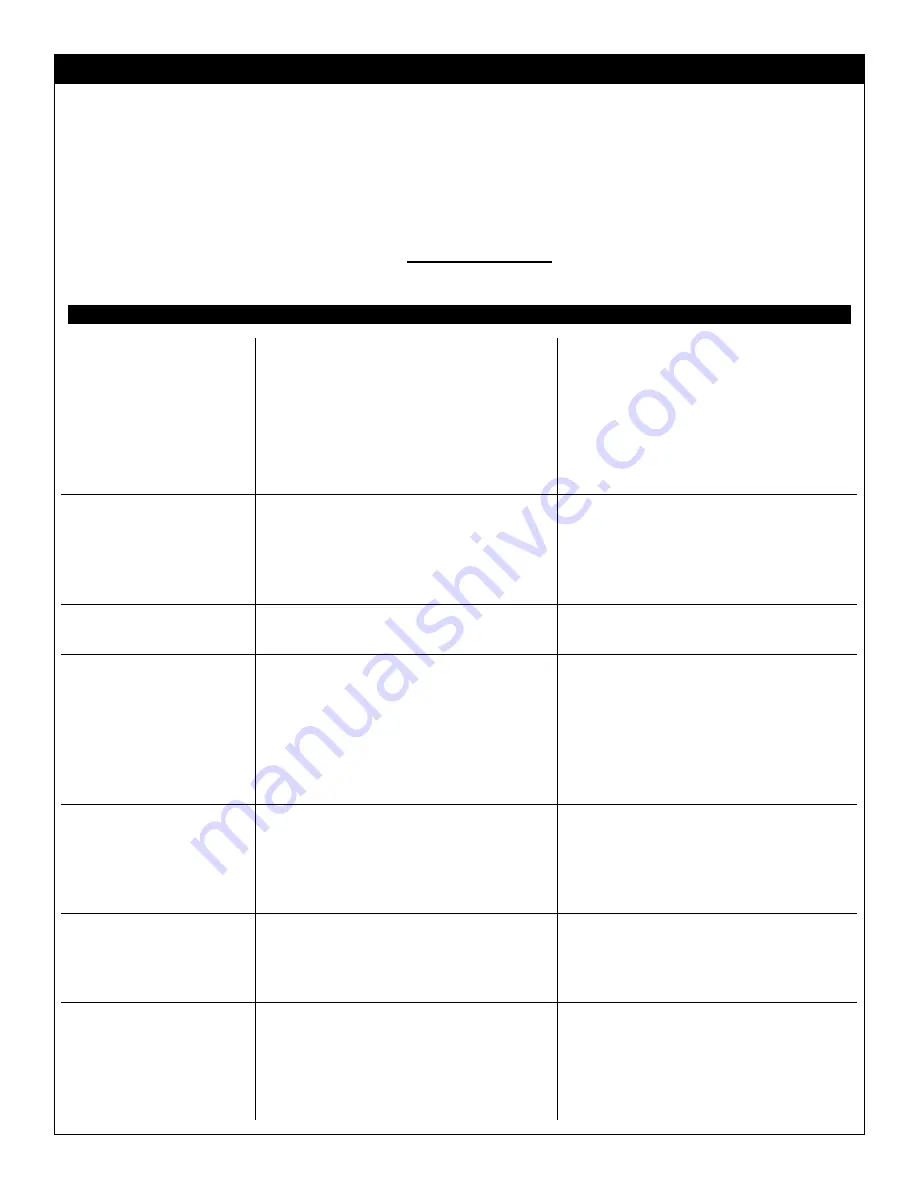

XLS .52A AIRCRAFT ENGINE TROUBLESHOOTING GUIDE

This troubleshooting guide has been provided to help you diagnose and solve most problems that you may encounter with your XLS series engine.

Most problems encountered can be solved by carefully following the problem-cause-solution sections below. If you cannot solve the problem using

this troubleshooting guide, please feel free to contact us using the information below.

1) Engine does not start

A) Failed glow plug

A) Replace glow plug with new one

B) Glow starter not charged and/or faulty

B) Fully charge glow starter and/or replace

C) Engine not being turned over fast enough

C) Use an electric starter to start engine

D) Low speed needle valve set too lean

D) Reset low speed needle valve to factory setting

E) Old or contaminated fuel

E) Replace with new fuel

F) Engine flooded with too much fuel

F) Remove glow plug and expel fuel from cylinder

G) Faulty fuel tank and/or stopper assembly

G) Check and/or replace fuel tank assembly

H) Air leak in fuel system and/or engine

H) Replace fuel lines and/or tighten all engine bolts

2) Engine does not draw fuel

A) Air leak in fuel system and/or engine

A) Replace fuel lines and/or tighten all engine bolts

B) High speed needle valve fully closed

B) Reset high speed needle valve to factory setting

C) Low speed needle valve set too lean

C) Reset low speed needle valve to factory setting

D) Fuel lines kinked

D) Check and straighten fuel lines

E) Defective fuel tank

E) Replace fuel tank

3) Engine vibrates excessively

A) Propeller out of balance

A) Balance propeller

B) Engine and/or engine mount loose

B) Tighten engine mounting bolts

4) Engine does not transition

A) Failed and/or wrong type glow plug

A) Replace with new recommended glow plug

B) Old and/or wrong type fuel

B) Replace with new recommended fuel

C) High speed needle valve set too rich

C) Set high speed needle valve to leaner setting

D) Low speed needle valve set too lean

D) Set low speed needle valve richer

E) Low speed needle valve set too rich

E) Set low speed needle valve leaner

F) Air leak in fuel system and/or engine

F) Replace fuel lines and/or tighten all engine bolts

G) Propeller too large

G) Replace with one size smaller propeller

5) Throttle barrel does not

A) Throttle servo linkage out of adjustment

A) Adjust throttle linkage to close throttle barrel

close completely

completely

B) Idle stop screw out of adjustment

B) Turn idle stop screw counter-clockwise until throttle

barrel closes fully

C) Low speed needle valve set too lean

C) Set low speed needle valve richer

6) Engine overheats

A) Engine running too lean

A) Richen high speed needle valve

B) Cowl too restrictive

B) Open larger vents in cowling to allow air to exit

C) Wrong type of fuel used

C) Use fuel with recommended oil content and type

D) Engine not fully broken in

D) Allow engine further break-in time

7) Engine stops abruptly

A) Engine running too lean

A) Richen high speed needle valve

B) Piston and sleeve out of tolerances

B) Return engine to Global Services

C) Engine overheating

C) See # 6 above

D) Low speed needle valve set too lean

D) Set low speed needle valve richer

E) Failed glow plug

E) Replace glow plug with new one

F) Fuel tank empty

F) Refill fuel tank

PROBLEm

CAUSE

SOLUTION

Global Services

18480 Bandilier Circle

Fountain Valley, CA 92708

Phone (714) 963-0329

Fax (714) 964-6236

Email: [email protected]

For product warranty inFormation, please reFer to the warranty card provided with your engine.