XL .52RFS AIRCRAFT ENGINE MAINTENANCE GUIDE

This maintenance information is provided to help you keep your new XL RFS series engine running in top form. Following this maintenance

information will ensure the long life and dependability you expect from your engine. Information is also provided to instruct you on how to adjust the

valves and how to reset the timing.

ADJUSTING THE VALVES

The valve gaps are preset from the factory, but do require periodic

adjustment. Check and adjust the valve gaps after the first 1 hour of

engine run-time. After that, the valve gaps can be checked and adjusted

about every 8 hours of run-time. The valves gaps will need adjustment

if you notice a severe loss of power or after you have repaired and/or

reassembled the engine.

IMPORTANT

Always adjust the valves when the engine is cold.

q

1) While the engine is cold, remove the valve cover on top of the

cylinder head by first unscrewing the two socket-cap screws.

q

2) Rotate the crankshaft until the piston is at top-dead center, verified

by looking through the glow plug hole. Both valves will be closed.

q

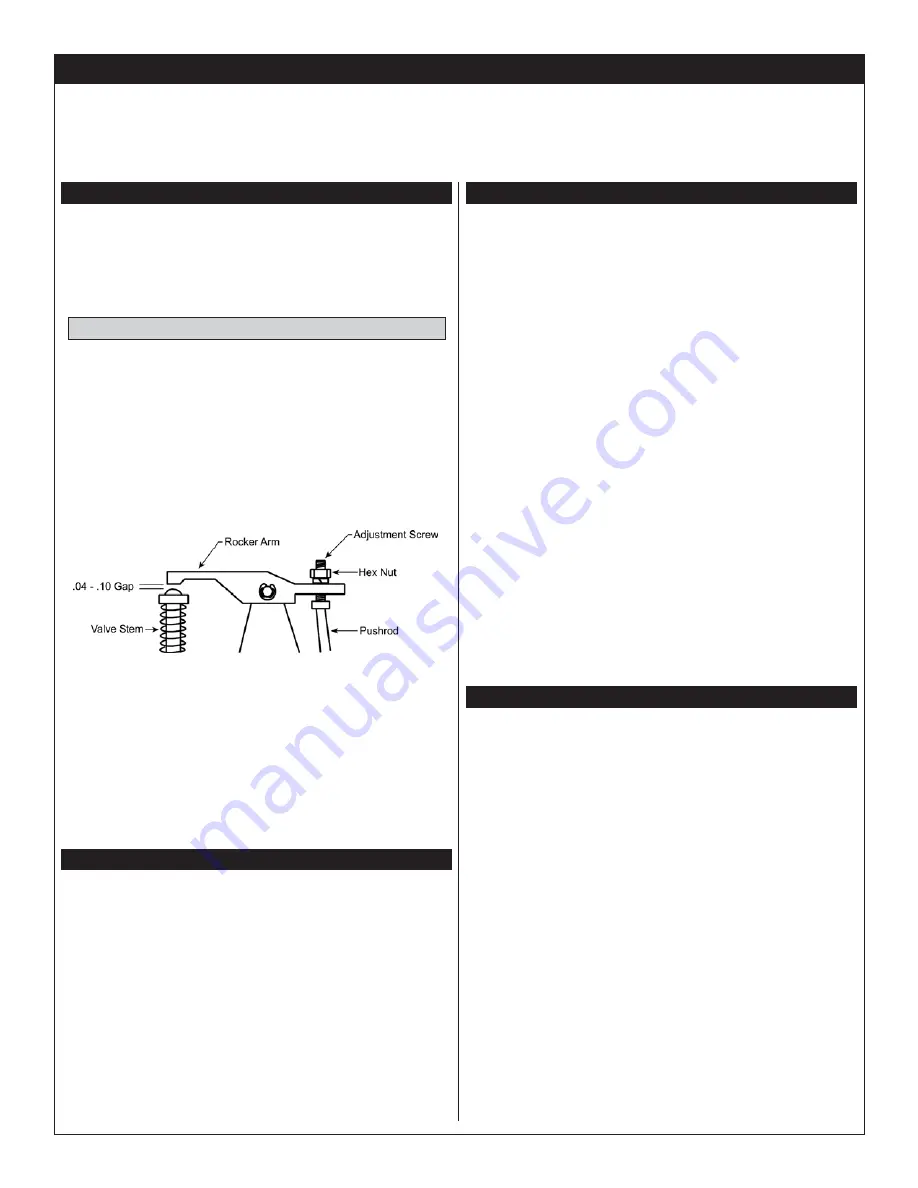

3) The required valve clearance is between .04mm and .10mm,

measured between the valve stem and the rocker arm. Use feeler gauges

(available at auto-parts stores) to check the clearance. The .04mm feeler

gauge should pass through the gap with only slight friction. The .10mm

feeler gauge should be tight.

q

4) Working with one valve at a time, loosen the locking nut, using

a small wrench. Use a screwdriver to turn the adjustment screw

counterclockwise about 1/2 turn. This will open the gap slightly. Slide

the .04mm feeler gauge between the rocker arm and the valve stem.

Carefully turn the adjustment screw clockwise until the rocker arm touches

the feeler gauge. Using a small wrench, tighten the lock nut.

q

5) Remove the feeler gauge and double-check the gap. Repeat step

# 4 if necessary to achieve the correct setting, then repeat the process

for the second valve assembly.

The timing must be reset if the crankshaft and/or camshaft has been

disassembled. In very rare cases the timing may need to be reset to

restore performance.

q

1) Remove the camshaft housing cover on the side of the crankcase

by first unscrewing the two socket-cap screws.

q

2) Rotate the crankshaft until the piston is at top-dead center, verified

by looking through the glow plug hole.

q

3) With the piston at top-dead center, position the camshaft with the

small punch mark facing toward you and pointing down toward the bottom

of the crankcase. Install the camshaft so that the punch mark is one tooth

ahead (toward the front of the engine) of the 6 o'clock position.

q

4) Reinstall the camshaft housing cover.

RESETTING THE TIMING

MAINTENANCE

Engine maintenance should be done on a regular basis to ensure that you

keep the engine running in top form, especially over time. Following these

simple maintenance practices will ensure the long life and dependability

you expect from your engine.

l

Avoid running the engine under dusty conditions. If you are in a dusty

environment, we suggest using an air filter over the carburetor.

l

At the end of every flying day, purge the engine of fuel by disconnecting

the fuel line from the carburetor and allowing the engine to run dry of fuel.

l

Use a high-quality after-run oil in the engine after you have purged

the engine of fuel. Inject the oil into the engine through the carburetor

and through the glow plug hole. Rotate the crankshaft several times to

distribute the oil throughout the engine. This will prevent rust from forming

inside the engine, especially on the ball bearings.

l

Wipe the outside of the engine dry using a soft cloth.

l

Use a fuel filter between the fuel tank and the carburetor.

l

Periodically check to make sure all of the engine bolts are tight, including

the muffler and exhaust pipe cinch nuts.

l

Periodically check your fuel system, including the plumbing inside the

fuel tank, for leaks or cracks. We recommend changing the silicone fuel

tubing inside and outside the fuel tank at the start of every flying season

or about once a year.

l

If you have attached a length of fuel tubing to the crankcase breather

nipple, periodically check the tubing for any blockage.

LONG TERM STORAGE

If you will not be using your engine for a long period of time, such

as during the winter, we suggest you take the following precautions to

preserve the reliability of your engine:

l

Run the engine completely dry of fuel as described above. This is

extremely important.

l

Remove the valve cover and camshaft housing cover and apply a

generous amount of after-run oil on and around the rocker arm assembly

and the camshaft. Reinstall the covers.

l

Remove the engine backplate and apply a generous amount of after-run

oil to the engine crankcase and to the rear ball bearing, then reinstall the

backplate.

l

Apply a generous amount of after-run oil to the joint between the

throttle barrel and the carburetor housing to prevent the throttle barrel

from sticking.

l

Remove the glow plug and apply a generous amount of after-run oil into

the cylinder head. Reinstall the glow plug and turn the crankshaft over

several times to distribute the oil.

l

Place the engine in a sealed baggie and remove as much air from the

baggie as possible. Your engine can now be stored for a long period

without worrying about rust or engine degradation.