2. SPDT reed switch: Connect wiring to terminals per wiring

diagram in Figure 4. Connect wiring to flying leads per

wiring diagram in Figure 5.

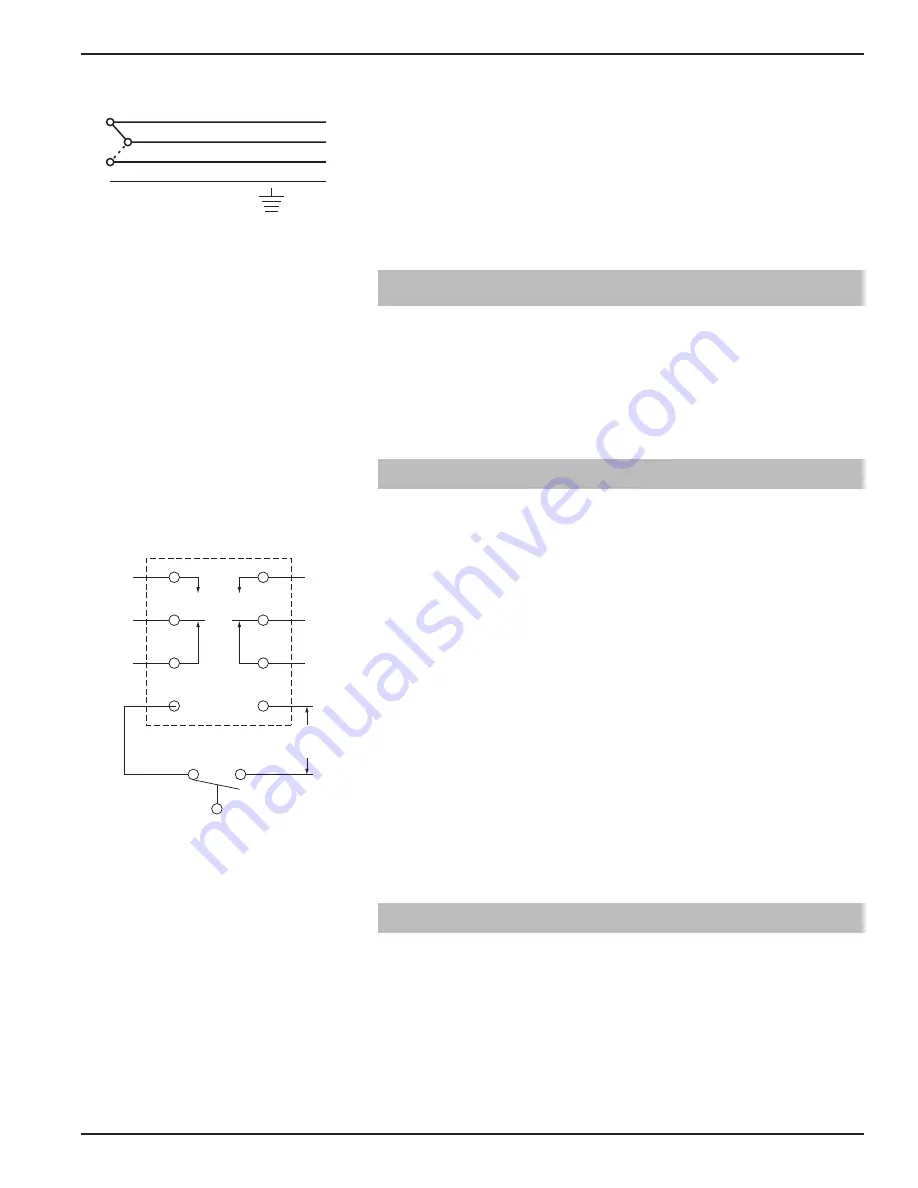

3. DPDT relay: Connect wiring to proper switch leads and

run power supply according to the wiring diagram. See

figure 6. This relay must be powered to function. 5A @

24 VDC relay requires 24 VDC power supply while the

5A @ 120 VAC relay requires 120 VAC power supply.

NOTE: Observe all applicable electrical codes and proper wiring

procedures.

2.0

Preventive Maintenance

Periodic inspections are a necessary means to keep your level

control in good working order. This control is a safety device

that protects the valuable equipment it serves. A systematic

program of preventive maintenance should be implemented

when the control is placed into service. If the following

instructions are observed, your control will provide reliable

protection of your equipment for many years.

2.1

Recommended Practice

2.1.1 Keep Control Clean

If applicable, be sure the switch housing cover is always in

place. This cover protects against damaging moisture and

acts as a safety feature by keeping bare wires and terminals

from being exposed. Should the housing cover become

damaged or misplaced, obtain a replacement immediately.

2.1.2 Inspect Connections Monthly

TK1 level switches may sometimes be exposed to excessive

heat or moisture. Under such conditions insulation on electri-

cal wires may become brittle, eventually breaking or peeling

away. The resulting bare wires can cause short circuits. Check

wiring carefully and replace at first sign of brittle insulation.

Check all electrical connections to ensure that they are tight.

Check wiring carefully and repair or replace if necessary.

2.1.3 Inspect Entire Model TK1 Unit Periodically

A periodic cleaning of the float, pivot and magnet assembly

will ensure continued free movement of the mechanism.

2.2

What to Avoid

1. NEVER leave the switch housing cover off of the control

longer than is necessary to make routine inspections.

2. NEVER place a jumper wire across terminals to “cut-out”

the control. If a jumper is necessary for test purposes, ensure

that it is removed before placing the control into service.

3. NEVER use in systems containing iron particles. The magnet

in the float assembly can attract the particles and become

jammed.

4. NEVER put insulation over the switch housing.

44-608 TK1 Liquid Level Switch

5

Figure 6

DPDT wiring diagram

BROWN

N.O.

GRAY

COM.

YELLOW

N.C.

BLUE

N.O.

WHITE

COM.

ORANGE

N.C.

RED

120 VAC or

24 VDC

LEVEL SWITCH

N.O.

RED

Figure 5

SPDT wiring for flying leads

Red NC

Orange NO

Green

Black C