5

WIRING (cont.)

SWITCH DIFFERENTIAL ADJUSTMENT

The standard differential of Series 75 level controls may be

field adjusted. Adjustment may be necessary if a wider

differential needs to be set to overcome switch chatter

caused by the process.

The differential, or the amount of level travel between

"switch-on” and "switch-off", may be adjusted by

repositioning the lower jam nuts on the float stem. This

adjustment is different for high level and low level

controls. Please refer to the appropriate section below for

adjustments instructions.

CAUTION:

Maximum differential adjustment is 25 mm (1”)

LOW LEVEL CONTROLS

On low level controls the switch trips on the lower actuation

point and resets on the higher actuation point. Widening

the differential will allow the switch to trip on the original

actuation point and reset at a later, or higher, point.

The differential on low level controls may be adjusted by

repositioning the lower jam nuts on the float stem. The

standard factory setting is for a minimum amount of play

(gap) between the top jam nuts and the attraction sleeve as

shown in Figure 6.

1.

Determine what change in differential is necessary.

NOTE: To widen the differential 25 mm (1"), the lower jam

nuts must be set proportionately lower on the stem [i.e. in

this example 25 mm (1")].

2.

Make sure power source is turned off.

3a. NEMA 4X/7/9 - Unscrew and remove switch housing

cover.

3b. CENELEC and BASEEFA - Loosen cover set screw,

unscrew and remove housing cover.

4. Disconnect power supply wires from switch mecha-

nism. Pull wires out of conduit connection opening in

housing base. See Figure 5.

5. Perform system shut-down procedures as required to

relieve pressure from float chamber of control. Allow

unit to cool.

a. Close shut-off valves (if so equipped) to isolate

control from tank. Drain off liquid in float chamber.

See Figure 3 on page 4.

b. On installations without shut-off valves, relieve

pressure from the tank. Drain liquid in tank to a level

below the connections of the float chamber.

NOTE: Level control, connections and pipe lines need not

be removed from the tank.

6.

Loosen enclosing tube nut with a 35 mm wrench.

Unscrew enclosing tube counterclockwise (switch

and housing base will rotate also), until it is free.

See Figure 5.

7.

Lift enclosing tube, switch, and base off float chamber.

Jam nuts and attraction sleeve are now accessible.

8. Measure the distance “D” from the top edge of the

upper jam nuts to the top of the float stem. See Figure

7. Record this measurement.

9. Loosen and remove upper jam nuts, guide washer and

attraction sleeve.

10. Loosen and adjust lower jam nuts to the desired

position. Tighten lower jam nuts securely. See Figure

7.

11. Replace attraction sleeve on stem.

12. Replace upper jam nuts and guide washer on the stem

in the position previously noted. Tighten upper jam

nuts securely. See Figure 7.

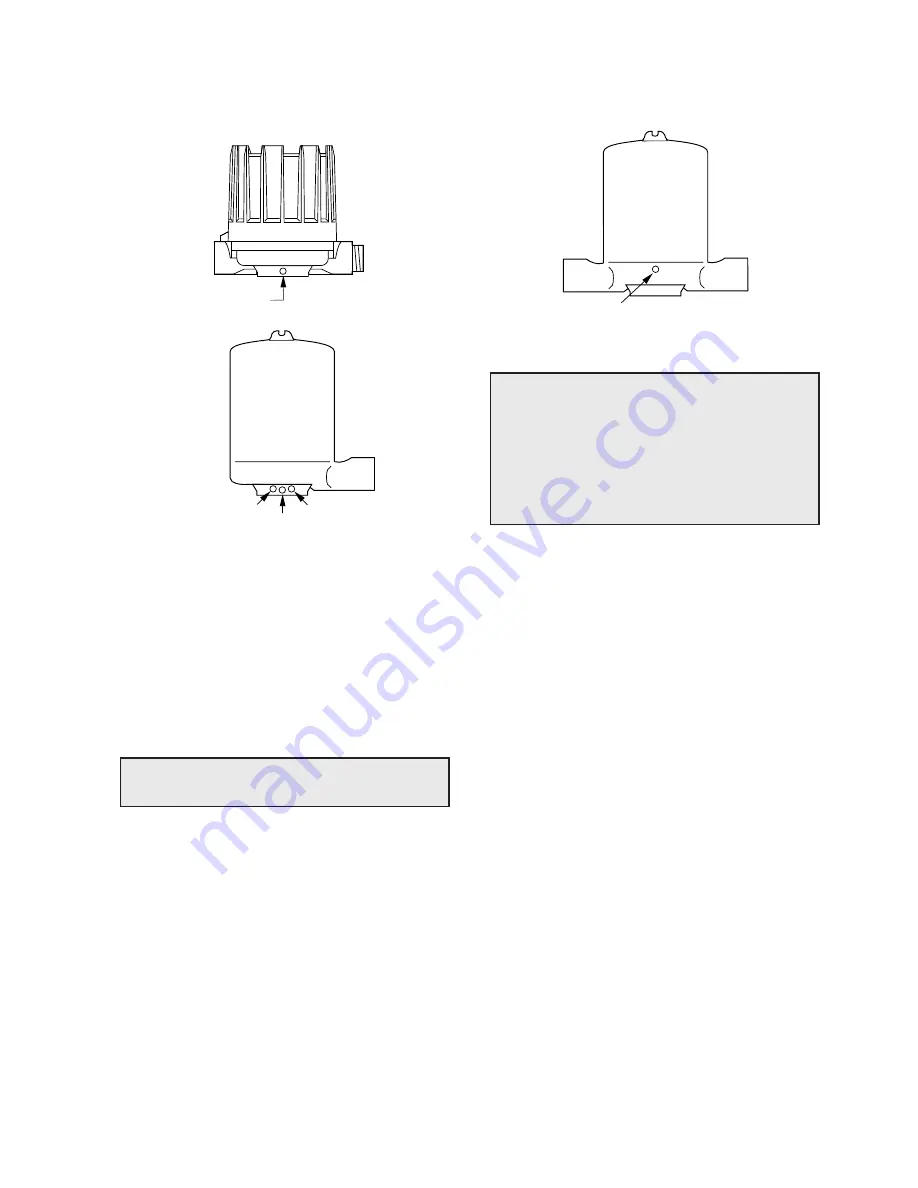

Set screw

Set screw

Locking screw

Set screw

Position

screw

CAUTION:

- DO NOT attempt to reposition NEMA 4 /

NEMA 7/9 housings without loosening the

set screws; CENELEC/BASEEFA housings

MAY NOT BE REPOSITIONNED. ALWAYS

retighten set screw(s) after repositionning.

- DO NOT attempt to unscrew cover of CEN-

ELEC/BASEEFA housings before loosening

locking screw in base of housing. ALWAYS

retighten locking screw after replacing cover.

Figure 4c

Figure 4a

Figure 4b

NEMA 4x

NEMA 7/9

CENELEC/BASEEFA

OBSERVE ALL APPLICABLE ELECTRICAL CODES AND PROPER WIRING PROCEDURES

Содержание 075

Страница 13: ...13 ...