508196-01

Issue 2120

Page 9 of 18

Model Number

Filter Area

(in

2

)

*MHP4-12-09*

*MHP4-12-12*

265

3MHP4-12-18*

5MHP4-12-18*

310

7MHP4-12-18*

10MHP4-12-18*

360

*MHP4-12-24*

400

*MHP4-12-30*

515

*MHP4-14-36*

600

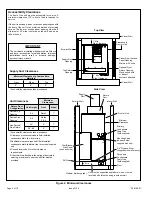

Table 5. Minimum Required Surface Area for

Disposable Filters

Condensate Drain

Provisions must be made to properly drain the primary and

secondary drain pans of this appliance.

Primary drain and secondary drain connection: 3/4” NPT to

3/4” PVC fitting (schedule 40 minimum). Both drains must

be trapped as shown in Figure 7. The drain line should

pitch gradually downward at least 1” per 10’ of horizontal

run to an open drain.

Figure 7. Condensate Drain Installation

If local codes require the use of metal condensate lines,

do not thread metal fittings into the unit drain pans. Thread

a PVC fitting into the unit drain pans and make the field

connection to the PVC fitting.

NOTE:

These units are designed with a redundant drain

system to handle condensate without the need for an

emergency drain pan. Should the indoor coil condensate

drain system fail, all water is contained within the unit and

the flow is directed into the unit base pan. From there it

will drain into the condensate riser. If for some reason the

water cannot drain into the main condensate riser, all water

is contained in the unit, and the design will allow drainage

out through the wall sleeve and louver to the outside of the

building.

Use thread sealant on the threaded fittings. Install

threaded fittings by hand only.

Do not over torque the

fittings.

Do not thread metal condensate fittings to unit drain

pans.

CAUTION

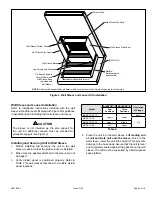

Ventilation Air

Units ship with a panel installed that seals the return air

compartment at the ventilation air intake. Installers can

choose to remove the factory-installed panel and use

the field-provided ventilation damper if introduction of

ventilation air is desired.

NOTE:

If ventilation air is introduced, the quantity of air

and conditions of this air must be accounted for in the load

calculations.

The auxiliary panel has nine knockouts to configure

ventilation air flow to installation requirements. Use Table

6 and Figure 8 to determine which knockouts to remove

from the auxiliary panel in order to achieve the desired

ventilation air flow. Use a flat head screw driver to remove

the knockouts. Set the factory-installed panel aside for

possible future changes.

The location of ventilation air capable models must

conform to the requirements of National Fire Protection

Association NFPA No. 54 in regards to proximity

of forced air inlets to flue gas terminals. Improper

installation could result in personal injury or death.

WARNING

Figure 8. Auxiliary and Factory Panel for Ventilation

Air

Factory panel

Ventilation

Air Duct

Auxillary panel

with knockouts

1

2

3

4

5

6

7

8

9