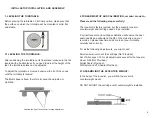

INITIAL SETUP, INSTALLATION, AND ASSEMBLY:

PLATTER

SPINDLE

CERAMIC BALL

In the following manual, we will cover all the basics needed to set

up your new T3 turntable.

1. INSTALLATION REQUIREMENTS:

It is imperative to place the turntable on a firm, non-vibrating,

horizontally leveled, and solid support.

2. ASSEMBLING THE BEARING AND PLATTER:

2.1:

Carefully insert the ball bearing into the spindle hole. The ball

bearing is made from ceramic. If the platter is dropped too hard

when placing it, the ball bearing can break.

2.2:

Insert the spindle into the hole carefully, allowing the air to

flow outside of the bearing structure. The bearing has been

pre-lubricated from the factory, and it should be cleaned and

lubricated with thin oil after every 100 hours of use.

2.3:

Carefully place the platter on the spindle. DO NOT twist, drop

or force the platter into position; this could damage the bearing

and will void the warranty.

In the next image, we can see the correct order in which all the

pieces should be assembled.

The platter should spin freely after everything is in place.

5

SPINDLE HOLE ON

TURNTABLE BASE

Содержание TT10

Страница 1: ...TT 10Turntable User Manual...