MAINTENANCE SCHEDULE

General

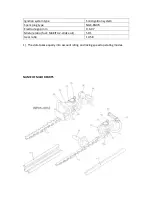

Engine assembly

Screws and nuts

Visual inspection for damage and tightness

Check for general condition and security

After each

refueling

Throttle lever

Safety lock key

STOP switch

Functional check

Functional check

Functional check

Daily

Air filter

Cooling air duct

Cutting tool

Idling speed

To be cleaned

To be cleaned

Check for damage and sharpness

Inspection (cutting tool must not move)

Weekly

Spark plug

Muffler

Inspection replace if necessary

Check and if necessary clean the opening

Quarterly

Suction head

Fuel tank

To be replace

To be cleaned

Shutting down

procedure

Fuel tank

Carburetor

Empty fuel tank

Operate until engine runs out of fuel

FAULT LOCATION

Fault

System

Observation

Cause

Engine not

starting or

under

difficulties

Ignition system

Ignition

spark is

present

Faulty fuel supply or compression system,

mechanical defect

No ignition

spark

STOP-switch operated, wiring fault or short

circuit, spark plug or connector defective,

ignition module faulty

Fuel supply

Fuel tank

filled

Incorrect choke position, carburetor

defective, suction head (gas line filter) dirty,

fuel supply line bent or interrupted

Compression

Inside of

engine

Cylinder bottom gasket defective,

crankshaft seals damaged, cylinder or

piston rings defective

Outside of

engine

Improper sealing of spark plug

Mechanical

fault

Starter not

engaging

Broken starter spring, broken parts inside of

the engine

Tank filled

Ignition

spark

Carburetor contaminated, have it cleaned

Содержание ST-HT260B

Страница 16: ...trabalhar Pouse a m quina desligue a e retire os res duos...

Страница 17: ...INSTRU ES DE MANUTEN O...

Страница 38: ...INSTRUCCIONES DE MANTENIMIENTO...

Страница 60: ...The blades will wear with long use When you find that trimming is not a good as when...