214880

47

Revision A

3.9

Reconfiguring Cutterbar Crop Stream

Discs are factory-installed to produce four crop streams, but disc rotation pattern can be changed by substitution of spindle

and corresponding disc to suit crop conditions. Each spindle and disc pair is designed to rotate in one direction and must be

changed as sets when altering crop flows.

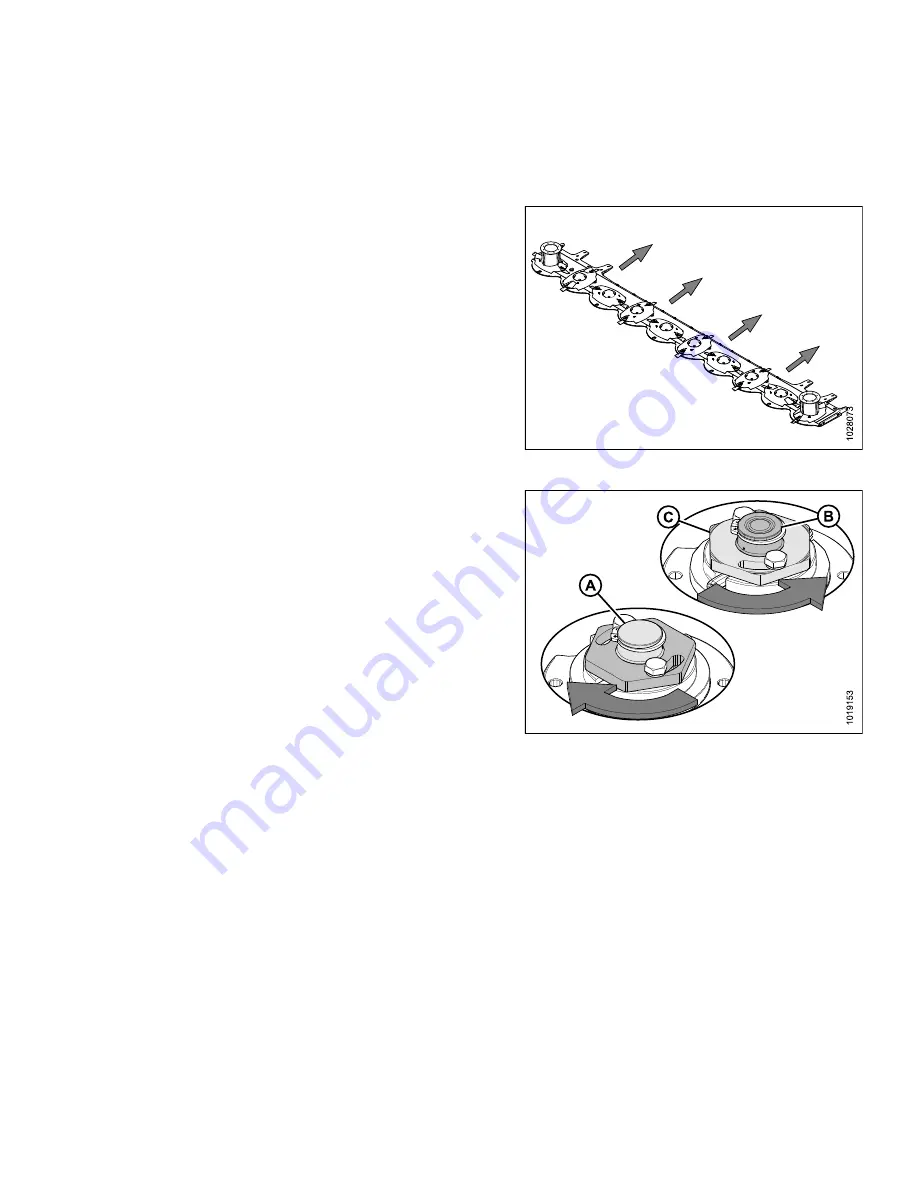

Figure 3.56: R216 Cutterbar

Reducing or increasing the number of crop streams will produce

the following results:

•

Reducing the number of crop streams will result in narrower

windrows.

•

Increasing the number of crop streams will result in

smoother, wider windrows.

NOTE:

Increasing the number of crop streams will also increase the

number of diverging disc pairs which may negatively affect

cut quality in certain conditions.

Figure 3.57: Cutterbar Spindles

IMPORTANT:

•

Spindles that rotate clockwise have right-leading threading

and are identified by a smooth top on the spindle gear

shaft (A).

•

Spindles that rotate counterclockwise have left-leading

threading and are identified by machined grooves on the

spindle gear shaft (B) and nut (C).

•

If spindle position in cutterbar has changed, the rotational

direction of that spindle

MUST

remain the same (that is, a

clockwise spindle must maintain its clockwise rotation).

•

Failure to maintain rotation pattern can result in damage to

spindle and/or cutterbar components.

•

Safecut (shear pin) will not work if spindles used in the

wrong orientation.