9

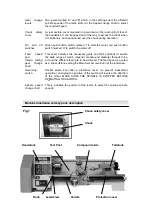

Fig 5

Reversing switch (under cover)

Door for change

gear compartment

Protective cover, enclosing the motor pulley, the drive pulley and drive

belt and the change gears. The gear cover operates an interlock

microswitch that will prevent the motor being started if the cover is not

closed.

Oil drain plug

The oil drain plug is a hex head bolt with a sealing washer located low

down at the rear of the headstock gear box, - when refitting the oil

drain plug ensure that the mating faces of the headstock and the

sealing washer are clean.

Headstock cover

plate

The headstock cover plate is a flat metal plate secured to the top of

the headstock gearbox by four cap head bolts. Unscrew the bolts and

remove the cover to inspect the gearbox or replace or top up the oil.

There is no gasket beneath the cover plate, so ensure the mating

surfaces are clean before replacing the cover.

18T reversing

The 18T reverse tumbler gear, when fitted, enables the rotation of the

leadscrew to be reversed, For left hand threads (as Fig 6) or in the

case of an asymmetric change gear selection to allow the leadscrew

to maintain its correct rotation (as Fig 7).

Fig 11 shows the reverse tumbler gear fitted in the gear train.

Oil sight glass

The oil level sight glass enables you to check the amount of oil you

have in your lathe.

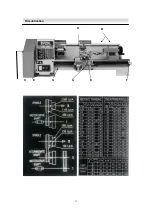

Identification and Description of the parts

Identification and Description of the parts of the BV20-BL Lathe

Содержание BL200L

Страница 1: ...N Index of Contents BENCH LATHE BL200L BV20L OPERATION MANUAL ...

Страница 10: ...10 ...

Страница 13: ...13 D H E G A C F Oil Lubrication Identification and Description of the parts of the BV20 BL Lathe B ...

Страница 14: ...14 ...