11

INSTALLATION INSTRUCTION

The machine is equipment with power voltage compensation equipment. When power voltage moves

between±15% of rated voltage, it still can work normally.

When use long cable, in order to prevent voltage form going down, bigger section cable is suggested. If

cable is too long, it may affect the performance of the power system. So we suggest you to use

configured length.

1. Make sure intake of the machine not blocked or covered, lest cooling system could not work.

2. Make sure the earth end of power interface has been reliably and independently grounded.

3. Correctly connect the arc torch or holder according to the sketch. Make sure the cable, holder and

fastening plug have been connected with the ground. Put the fastening plug into the fastening

socket at the “-”polarity and fasten it clockwise.

4.

Put the fastening plug of the cable to fastening socket of “+” polarity at the front panel, fasten it

clockwise, and the earth clamp at the other terminal clamps the work piece.

5. Please pay attention to the connecting polarity, DC welding machine has two connecting ways:

positive connection and negative connection.

Positive connection: holder connects with “-” polarity,

while work piece with the “+”polarity. Negative connection: work piece with the “-”polarity, holder

with the “+” polarity. Choose suitable way according to working demands. If unsuitable choice, it will

cause unstable arc, more spatters and conglutination. If such problems occur, please change the

polarity of the fastening plug.

6. According to input voltage grade, connect power cable with power supply box of relevant voltage

grade. Make sure there is no mistake and make sure the voltage difference among permission

range. After the above job, installment is finished and welding is available.

Attached components type list

Mode

ARC 400IT

Rated current of Power switch

32A

Cable

Input side

≥4mm2

Output side

50mm

2

Earth cable

≥4mm

2

Electrode holder

Electrode holder above 500A is

suggested.

If distance of work piece and machine is too far (500-100m), and the cables (torch

cable and earth cable) are too long, please choose cable of bigger section to

minimize the reduction of the voltage.

Содержание ARC 400IT

Страница 1: ...ARC 400IT WELDING MACHINE USER MANUAL...

Страница 12: ...12 Installation Diagram Power Supply Workpiece Earth Clamp Electrode Holder...

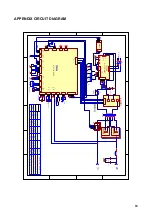

Страница 20: ......

Страница 21: ......