MAAG-14000-E-02EMEA

7

S SERIES TWIN SCREW PUMPS

S E C T I O N 4

O P E R AT I O N

PUMP PREPARATIONS

The final pre-startup check is very important to avoid operational

difficulties . Listed below are several key components to be checked

prior to pump operation:

STEP 1

Inspect all piping . Check individual piping support; check for leaks

and unnecessary piping strain on the pump; flush all piping to

ensure removal of foreign material from the system; check that

all valves and gauges are functional; check mesh-size suitability .

STEP 2

Ensure pump cavity is filled with pump fluid .

STEP 3

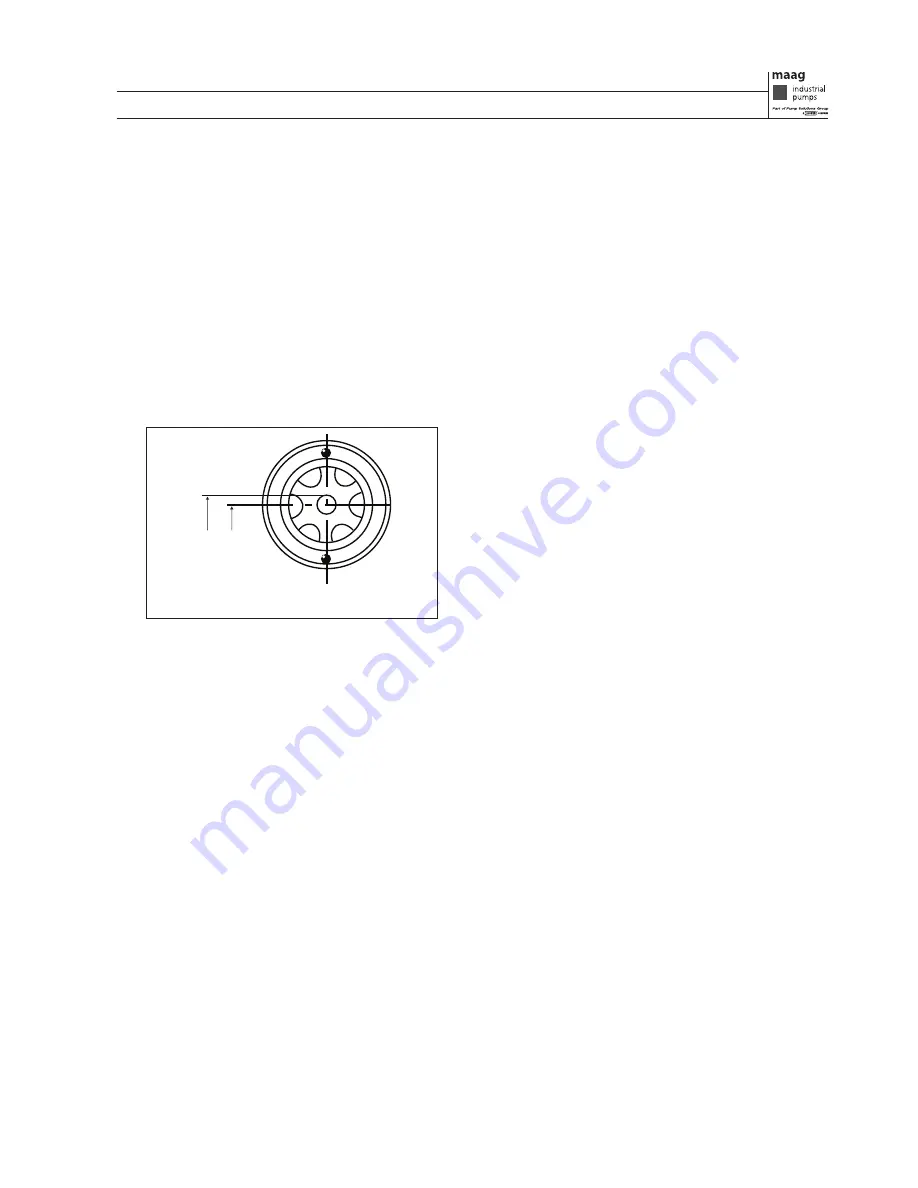

Check that oil is at the proper level in the gear housing . Excessive

oil will cause the gear box to overheat (see Figure 6) .

STEP 4

Check pressure gauges and all other meters .

STEP 5

Check all electrical equipment (i .e ., cables, control lines and

accessories) .

If pump is jacketed for heating, heat the pump casing to the

prescribed temperature . Steam, hot water and hot oil can

be used as a heating medium . According to the different

materials of the pump casing, select proper pressure for

heating medium within the limit of 2 .0 to 8 .0 bar (29 .0 to

116 psi) . Inlet and outlet are located on the pump casing;

therefore, the thermal difference between pumped fluid

and heating medium should be as small as possible in order

to avoid generating internal stress . Especially for cast-iron

pumps, the thermal difference between the pumped fluid

and the heating medium should be less than 50°C (122ºF) .

If the pump is installed with a double mechanical seal, then

sealing the liquid system is required . The pressure for sealing the

liquid system should be 1 .0 to 2 .0 bar (14 .5 to 29 .0 psi) higher

than that of the pump suction chamber . All rules and regulations

regarding sealing the liquid system should be adhered to as

described in the Sealing Liquid System Instructions .

STEP 6

Check rotation shafts by rotating the coupling by hand to

determine whether the pump shafts and motor shaft turn

freely . If any rubbing or binding occurs, the cause must be

located and corrected before starting the pump .

STEP 7

Check that motor rotation is correct; refer to the rotation

directional mark located on the pump .

STARTING THE PUMP

STEP 1

Open the suction and discharge valves wide in order to keep

the entire piping system unobscured .

NOTE: Ensure that all valves and devices on the suction and

discharge sides are opened before starting the pump .

STEP 2A

If pump is installed with a heating jacket, introduce heating

medium and heat the pump to the temperature as described

in previous section .

STEP 2B

If pump is equipped with double mechanical seals, introduce

sealing liquid and monitor the sealing liquid system .

STEP 3

Rotate the coupling by hand to determine if rubbing or

binding occurs .

STEP 4

Start motor/driver .

STEP 5

The pump must be stopped if there is no capacity after

starting . Restart the pump after several minutes . If there is still

no capacity, the cause must be determined . Please refer to the

Troubleshooting section of this manual for further instruction .

RUNNING THE PUMP

STEP 1

Check the pumping unit for unusual noise or vibration . Any

unusual vibration or change in sound must be investigated

and corrected to normal operating conditions .

STEP 2

Check bearing housing temperature . Bearing temperature

can safely rise to between 65°C and 75°C (149ºF and 167ºF) .

Pumped medium or spot environmental temperature should

be considered when determining whether temperature

exceeds normal operating conditions .

Bearing temperature up to 90°C (194ºF) is considered to be normal .

Within this limit, the stability of the temperature is the best indicator of

normal operation . A sudden increase in temperature indicates that a

bearing problem is developing and the bearing should be checked

immediately .

CAUTION: Do not attempt to measure the temperature by hand!

STOPPING THE PUMP

STEP 1

Stop the motor and pump .

STEP 2

Close suction and discharge valves .

STEP 3

If pump is installed with a heating device, stop the heating

device first, then close the sealing system after cooling .

FIGURE 6 Oil Level of the Gear Casing

max

min

Содержание S Series

Страница 12: ...S E C T I O N X NOTES...

Страница 13: ...S E C T I O N X NOTES...

Страница 14: ...S E C T I O N X NOTES...