M1EXS-2

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: [email protected]

EM-5986-A Rev.1 P. 4 / 5

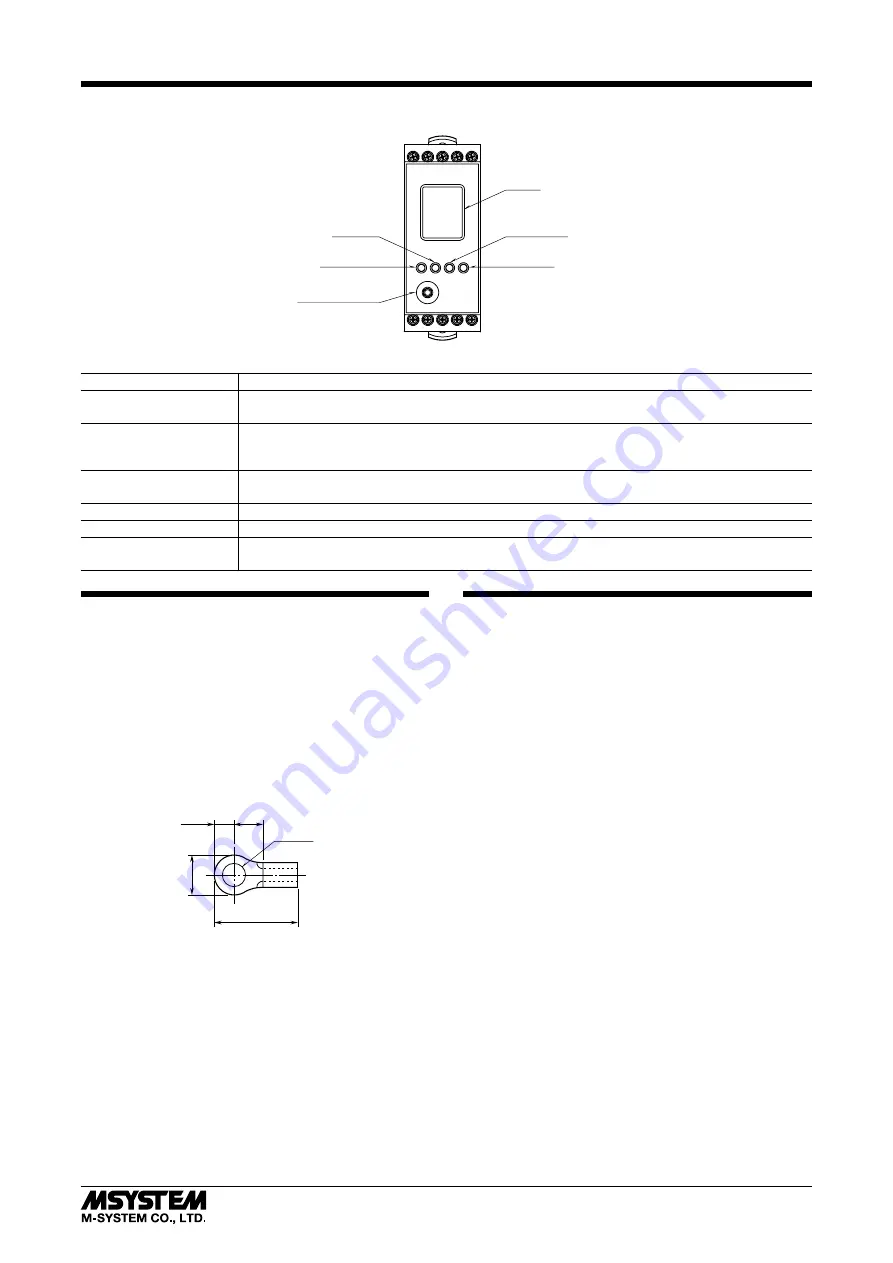

EXTERNAL VIEWS

Mode Button

Set Button

Display

Configurator Jack

Up Button

Down Button

COMPONENT

FUNCTION

Display

Indicates present values, setting values and abnormal information. Two types of present values at up-

per and lower are displayed by setting.

Mode button

Used to shift from measuring mode to each setting mode. Destination to shift is changed by the time

pressing and holding the button. Used to return from each setting mode to measuring mode (press and

hold for 2 sec. or more).

Set button

Used to change setting value of setting parameter. When at setting changeable state, used to enter

(save) the setting value. Used to move on through digits of setting value at setting changeable state.

Up button

Used to shift through setting parameter, and to increase or select setting value.

Down button

Used to shift through setting parameter, and to decrease or select setting value.

Configurator Jack

Used to configure with M1E configurator software (model: M1ECFG). At the same time, set the lockout

setting of the unit to ‘lock’.

WIRING INSTRUCTIONS FOR BASE

■

SCREW TERMINAL

Torque: 0.5 N·m

■

SOLDERLESS TERMINAL

Refer to the drawing below for recommended ring tongue

terminal size. Spade tongue type is also applicable.

Recommended manufacturer: Japan Solderless Terminal

MFG.Co.Ltd, Nichifu Co.,ltd (Solderless terminals with in-

sulation sleeve do not fit)

Applicable wire size: 0.25 to 1.65 mm

2

12max

6max

3max

4min

3.2 dia.

(mm)

CHECKING

1) Terminal wiring: Check that all cables are correctly con-

nected according to the connection diagram.

2) Power input voltage: Check voltage across the terminal

19 – 20 with a multimeter.

3) Input signal and power input voltage: Check wiring

across M1EXS-2 and self-synch as shown in connection

diagram. The power input of the unit has polarity. Be

sure that the connection for R1 and R2 of the self-synch.

4) Output: Check that the load resistance meets the de-

scribed specifications.