IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

72-20

March 2020

Page 173

IO-390-D Series Engine Maintenance Manual

(6)

Tie a loop of soft wire around the camshaft and left crankcase half (as shown in Figure

79) to hold the camshaft securely in place.

Figure 79

Example of Camshaft Wired to Crankcase Half

22.

Crankshaft Installation

CAUTION

BEFORE INSTALLATION, MAKE SURE THE CRANKSHAFT HAS

SATISFACTORILY PASSED THE MAGNETIC PARTICLE INSPECTION

AND DOES NOT HAVE ANY CRACKS. DO NOT INSTALL A

CRANKSHAFT WITH ANY CRACK(S). ENGINE MALFUNCTION CAN

OCCUR IF A CRANKSHAFT WITH A CRACK IS INSTALLED.

NOTICE:

The connecting rods are to have been already installed on the crankshaft per the

“Connecting Rod Installation” procedure in this chapter.

A.

Apply engine oil mixture (15% pre-lubricant (STP or equivalent) and 85% SAE No. 50

mineral base aviation grade lubricating oil) to the main bearing journals of the crankshaft and

the rear and center main bearing inserts in the right crankcase half.

B.

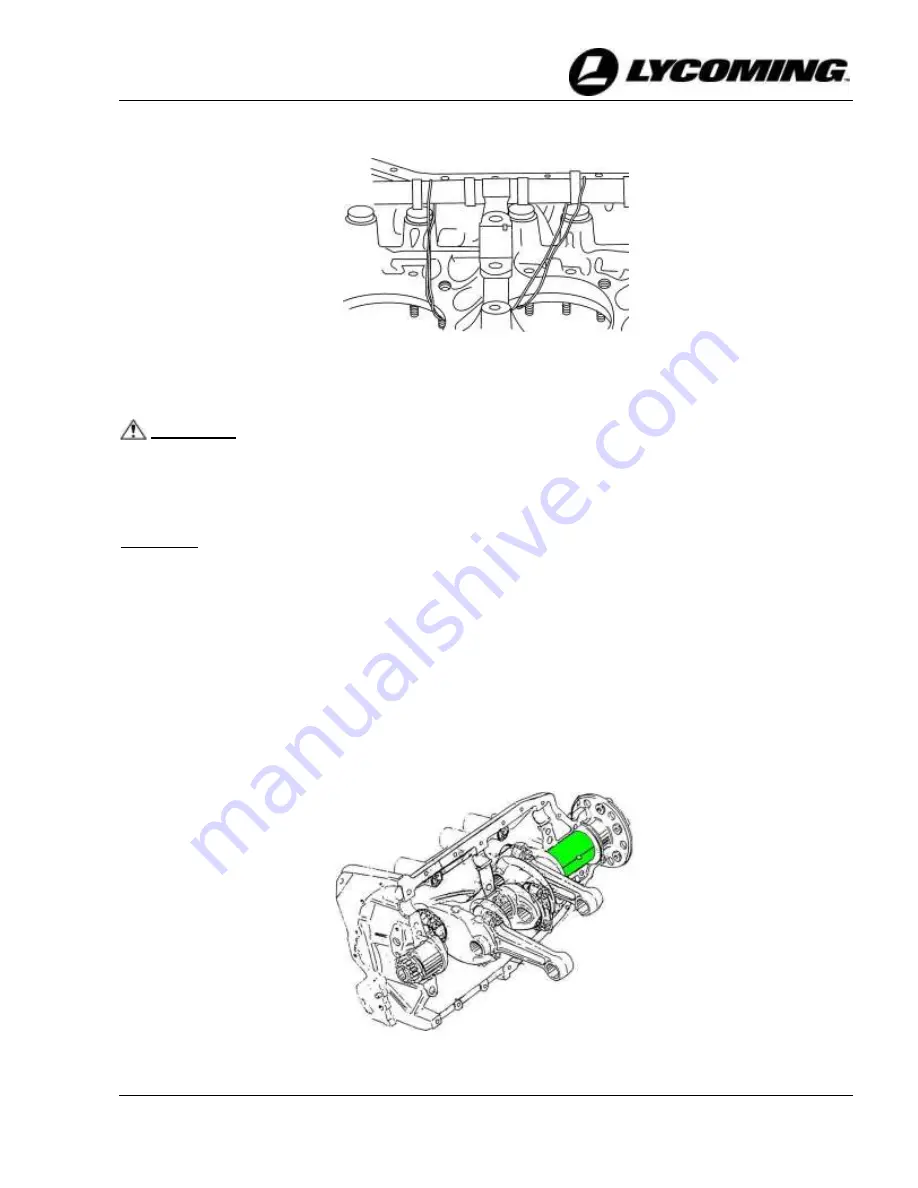

Install the Front Bearing Halves on the Crankshaft

(1)

Apply a coating of engine oil mixture to the front main bearing halves.

(2)

Install the front bearing halves, where they touch (butt together) around the crankshaft.

(3)

Lift the crankshaft assembly by the connecting rods. Lower the crankshaft assembly into

the crankcase half (Figure 80). Let the connecting rods extend through the cylinder base

openings in the crankcase half.

Figure 80

Crankshaft Installed in Crankcase Half