IO-390-D Series Engine Maintenance Manual

72-20

© 2020 Avco Corporation. All Rights Reserved

Page 164

March 2020

IO-390-D Series Engine Maintenance Manual

CAUTION

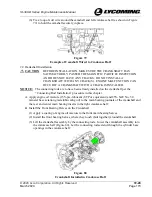

CORRECT INSTALLATION OF THE NEW NUT ON EACH NEW

CONNECTING ROD BOLT IS NECESSARY FOR CORRECT

CONNECTING ROD ASSEMBLY. EACH CONNECTING ROD NUT

HAS TWO DIFFERENT SURFACES, ONCE SURFACE IS FLAT AND

THE OTHER IS CHAMFERED AND HAS A RAISED LIP. BE SURE

TO INSTALL EACH NUT ON THE CONNECTING ROD BOLT WITH

THE FLAT FACE TOUCHING THE ROD. THE CHAMFERED

RAISED LIP SURFACE IS AWAY FROM THE ROD.

(9)

Install a new nut on each new connecting rod bolt where the flat face of the nut touches

the connecting rod as shown in Figure 51.

(10)

Torque the connecting rod bolts per the torque values in the latest revision of Service

Instruction No. SI-1458. (Stretch bolts require an initial torque and are then torqued to

the correct stretched length.)

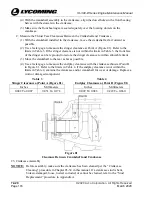

(11)

Measure the side clearance between the connecting rod and crankshaft with a feeler gage

where shown in Figure 52. The clearance is to be 0.004 to 0.016 in. (0.102 to 0.406 mm)

(service or overhauled) and 0.004 to 0.010 in. (0.102 to 0.254 mm) (on rebuilt engines).

Compare the results to the measurements previously recorded.

Figure 51

Connecting Rod Nut Installation

Figure 52

Connecting Rod Side Clearance

F.

Counterweight Installation

CAUTION

DURING INSTALLATION, DO NOT MAKE SCORES, SCRATCHES, OR

ETCH MARKINGS OF ANY KIND ON THE CRANKSHAFT,

COUNTERWEIGHTS AND ROLLERS. A MARK IN ANY OF THESE

AREAS CAN CAUSE THE PART TO WEAKEN AND TO FAIL.

(1)

Make sure the counterweights of the correct order and part number are to be installed on

the crankshaft. Refer to the latest revision of Service Instruction No. SI-1012.

CAUTION

DO NOT INSTALL TWO DIFFERENT ROLLERS ON THE SAME

COUNTERWEIGHT. ALL MUST BE MATCHED PAIRS OF

IDENTICAL PARTS.

(2)

Measure the outside diameter of each roller to be installed to make sure it is in

compliance with the dimensions in the latest revision of Service Instruction No. SI-1535.