EBS76 08

MAINTENANCE AND SERVICE

Maintenance and Service

Maintenance and Cleaning

Before any work on the dust collector itself, pull

the mains plug.

If the machine should fail despite the care taken

in manufacturing and testing procedures, repair

should be carried out by an approve service

centre.

- Regularly check to see if any dust or foreign

matter has entered the grills near the motor and

around the trigger switch. Use a soft brush to

remove any accumulated dust. Wear safety

glasses to protect your eyes whilst cleaning.

- Re-lubricate all moving parts at regular

intervals.

- If the body of the sander needs cleaning, wipe

it with a soft damp cloth. A mild detergent can

be used but nothing like alcohol, petrol or other

abrasive cleaning agents. Never use caustic

agents to clean plastic parts.

CAUTION!

Water must never come in to contact

with the sander.

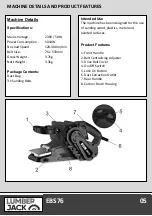

Replacing the Brushes

- During use, the carbon brushes will wear down

and will be indicated by a possible loss of power

and excessive sparking seen through the

ventilation slots.When the carbon brushes have

worn down to approximately 4-5mm, they will

require replacing.

-

Caution!

Make sure that the sander is isolated

from the mains power supply before fitting

accessories, maintenance and adjustment if in

doubt consult a qualified electrician.

- Place the sander on a workbench and using a

screwdriver remove the carbon brush housing

cover.

- Remove the carbon brush from the brush

housing and replace it with a new one. Slide the

new carbon brush in to the brush housing.

Repeat this procedure for the other carbon brush.

Then replace the carbon brush housing cover.

Note: Carbon brushes must be replaced in pairs.