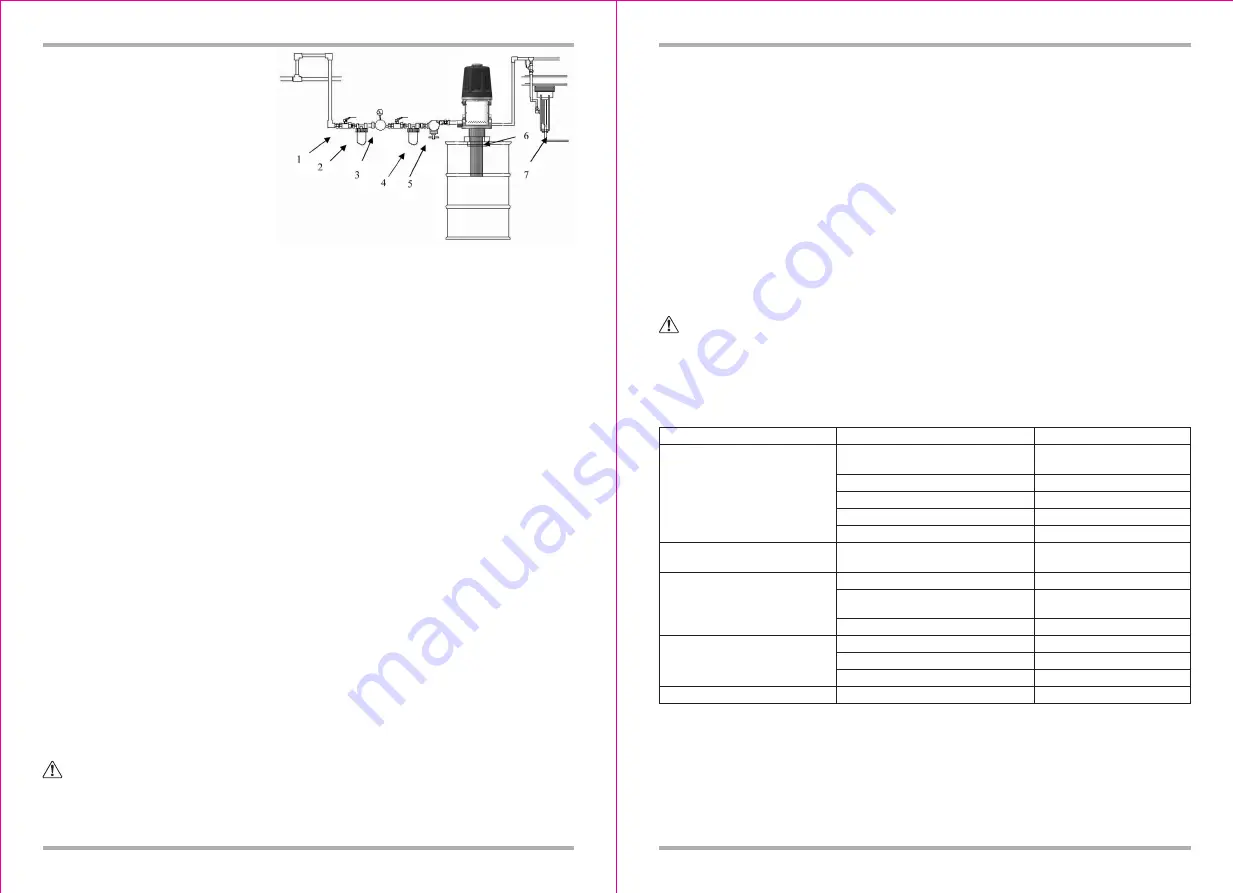

Fig.3: Oil supply system installation

4

3.2 Installation

3.2.1 Standard installation

1: cut-off valve

2: Filter

3: Regulator

4: Lubricator

5: Control valve

6: Locking adapter

7: Hose reel

The above installation is not the integrated oil supply system, just contact the manufacture or

distributor if you need. Installation for air circle.

3.2.1.1 Note: Do not hang any device at the air inlet, as there maybe dropping and damage.

3.2.1.2 Process

• Put the pump into lock adapter (Fig .3 Parts 6), Install to the trolley.

• Install cut-off valve (Fig3. Part1).

• Install filter (Fig 3. Part 2).

• Install regulator which control the speed and adjust the air pressure (Fig3. Part3).

• Install lubricator which with self-lubricate (Fig3. Part 4).

• Install control valve which control flux

,

When the speed is too fast, pump will be self-close

automatic to avoid pump be damaged (Fig.3 Parts5).

• Connect oil output.

3.3 Operation

3.3.1 Pressure Relief

3.3.1.1 Injury for skin

:

Before pressure relief by manual

,

Pump is under pressure

。

To reduce the

risk of serious injury from pressurized fluid, accidental spray from the valve, or splashing fluid, follow

this procedure whenever you

• Are instructed to relieve pressure

• Stop dispensing

• Check, clean, or service any system equipment

• Install or clean dispensing devices

3.3.1.2 Pressure Relief procedure

• Turn off the cut-off valve, shut off air

• Put the pump to the waste equipments, switch oil valve ,relief pressure

• Turn the air supply and oil fluid.

• Turn off the oil valve.

3.3.1.3. When occurs

:

• Problems on control valve, flexible hose, rigid tube or manual tip, auto tip.

• Pressure not relieve thoroughly according to above relief procedure.

• Pressure relieved very slowly until relieved thoroughly. Please clear obstruction of oil system.

3.3.2 Operation

3.3.2.1 Note: After initialize work, open the oil valve, pump start to work. Close the oil valve, pump

stop working.

3.3.2.2

WARNING:

Each device with different max working pressure. To reduce the risk of

exceed pressure. Make sure the max work pressure for each device. Rated pressure in the system

can not exceed the max pressure of any device. Or there will be burst, explosion, malfunction,

serious damage.

5

3.3.2.3 Remind: Pump can not operate with empty load. Or the speed will be very fast which will

self-damage.

If acceleration is too fast or running very slow, Should stop operation and check that if there is

enough oil in the barrel. If there is insufficient oil, change the trolley and initialize the whole system.

3.3.2.4 Startup

• If there is several pump in the whole system, please use control valve to dispatch the air.

• Open the main control valve.

• Open the oil valve which with effective grounding with the trolley. Keep the connecting of the

metal forboth oil valve and trolley. Open the cut-off valve, pump start to work. When the pump is

stable. Close theoil valve.

• If there are several pumps in the whole system, startup for each pump step by step with above

instruction.

• To get perfect result, set up the min air pressure for each device.

• Pump can not operate under empty load.

• Relief pressure before close the pump.

4 Trouble Shooting

WARNING:

To reduce the risk of serious injury whenever you are instructed to relieve pressure.

Do not remove silencer, or it may cause finger be injury.

4.1 Before check and maintain, pay more attention of the relieve of pressure.

4.2 Ordinary problems, reason and solution

Problem

Pump fails to operate

Continuous air exhaust

Erratic pump operation

Pump operates, but output low on

both strokes

Leakage from silencer

Solution

Cause

Inadequate air supply pressure or

restricted air lines

Closed or clogged dispensing valve

Clogged fluid lines, hoses, valves, etc

Damaged air motor

Exhausted fluid supply

Worn or damaged air motor gas-kit,

packing, seal, etc.

Exhausted fluid supply

Held open or worn intake valve or

piston packing

Hose damaged

Piston damaged

Seal O-ring damaged

Hose, valve or other device block

O-ring damaged

Increase air supply; clear

Open; clear

Clear

Service air motor

Refill and re-prime or flush

Service air motor

Refill and re-prime or flush

Clear; service

Change hose

Change piston

Change O-ring

Relieve pressure

Change O-ring