7

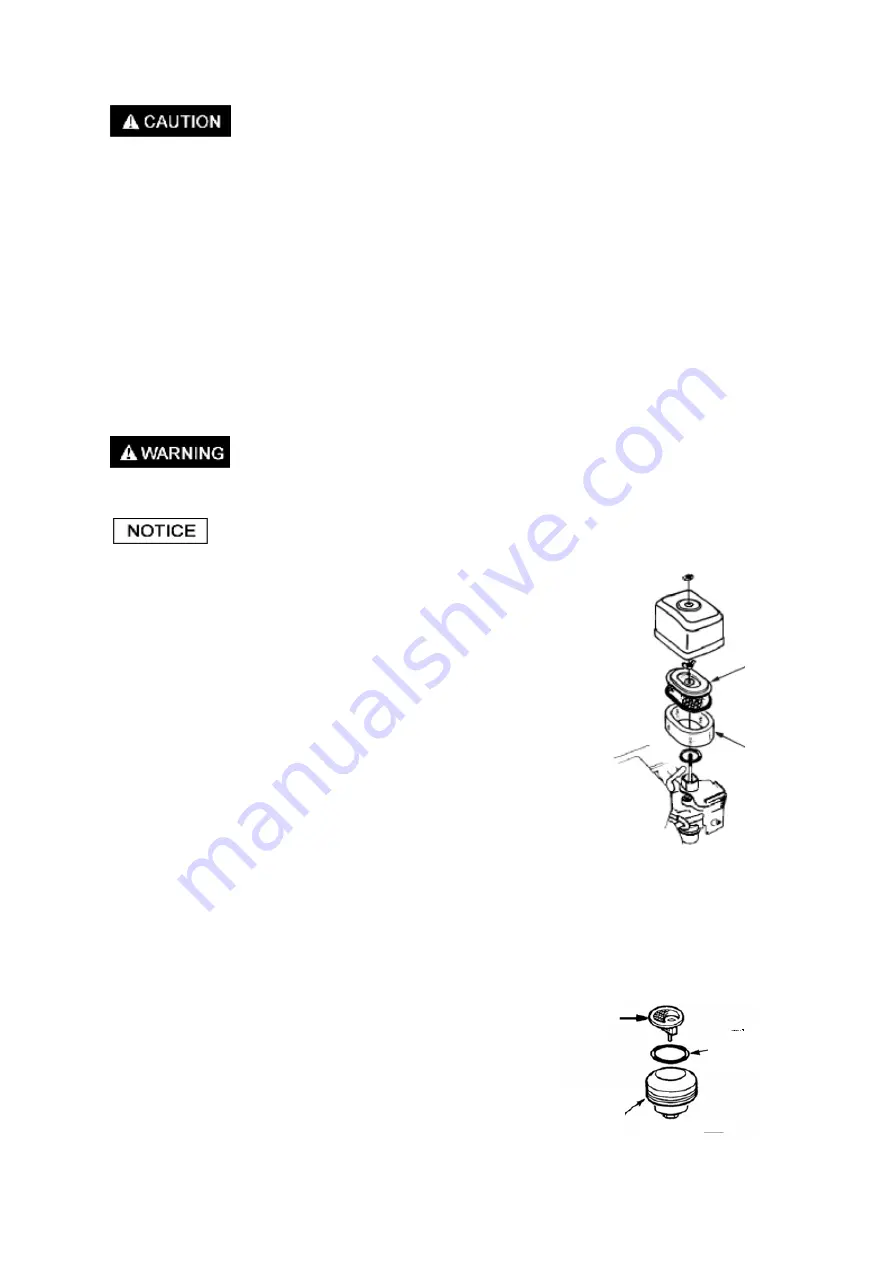

Paper

filter

Foam

filter

Figure 6

Engine oil may cause skin cancer if repeatedly left in contact with

the skin for prolonged periods. Although the skin cancer does not

necessarily happen, it is still advisable to thoroughly wash the

skin that has contacted engine oil with soap and water after handling engine oil.

For the sake of environment protection, please treat the used engine oil in an

appropriate way. We strongly advise you to store the used engine oil in a sealed

container and take it to the local service station or recycling center for reclamation.

Never throw it in the trash or pour it on the ground or into the ditch.

2. Air filter maintenance

A dirty air filter will restrict air flow into the carburetor. To prevent carburetor malfunction,

maintain the air filter regularly. Maintain it more frequently when operating the generator

in extremely dusty areas.

Using gasoline or inflammable solvent to clean the filter element

can cause a fire or explosion. Use only soapy water or nonflammable solvent.

Never run the generator without the air filter, or rapid engine wear

will result.

(1) Unsnap the air filter cover clips, remove the air filter

cover and check the filter element to confirm it is complete

and clean.

(2) If the foam element is dirty, clean it following the method

below:

Wash the element in a solution of household detergent and

warm water, or in a nonflammable detergent, or a high

flash point detergent; squeeze the element to thoroughly

remove the fluid in it. Drip some drops of engine oil into it.

If the paper element is dirty, gently knock it several times;

then use compressed air (with a pressure not higher than 207KPa)

to blow it from the inside to the outside. Never use a brush to clean the paper element,

or the air pores of the element will be clogged. If the paper element is damaged,

replace it with a new one (see Figure 6).

(3) Reinstall the air filter element and the cover, then tighten the screw.

3. Clean the fuel sediment cup

(1) Turn the fuel valve to the OFF position, remove

the fuel sediment cup, and take out the O ring and

strainer.

(2) Clean the sediment cup, o-ring, and strainer in a

nonflammable or high flash point solvent.

(3) Reinstall O-ring and strainer, and the fuel sediment

cup and tighten the cup.

Straine

r

O-ring

Sedimen

t cup

Figure 7