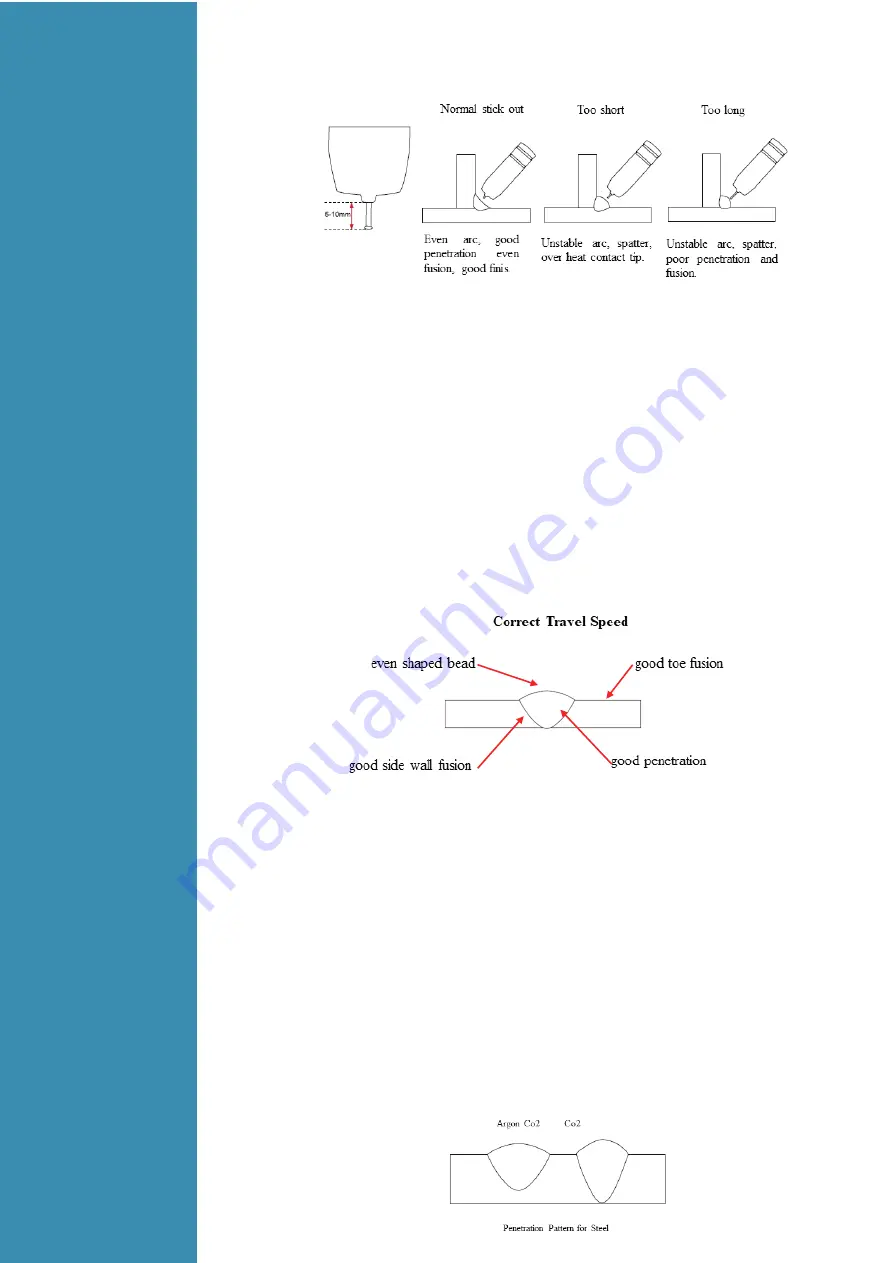

Travel Speed

- Travel speed is the rate that the gun is moved along the weld joint and is usually

measured in mm per minute. Travel speeds can vary depending on conditions and the welders skill and

is limited to the welders ability to control the weld pool. Push technique allows faster travel speeds than

Drag technique. Gas flow must also correspond with the travel speed, increasing with faster travel speed

and decreasing with slower speed. Travel speed needs to match the amperage and will decrease as

the material thickness and amperage increase.

Correct Travel Speed

- The correct travel speed keeps the arc at the leading edge of the weld pool

allowing the base metal to melt sufficiently to create good penetration, fusion and wetting out of the

weld pool producing a weld deposit of good quality.

Wire types and sizes

- Use the correct wire type for the base metal being welded.

Gas selection

- The purpose of the gas in the MIG process is to protect / shield the wire, the arc and the

molten weld metal from the atmosphere. Most metals when heated to a molten state will react with the

air in the atmosphere, without the protection of the shielding gas the weld produced would contain

defects like porosity, lack of fusion and slag inclusions. Additionally some of the gas becomes ionised

(electrically charged) and helps the current flow smoothly.

The correct gas flow is also very important in protecting the welding zone from the atmosphere. Too low

flow will give inadequate coverage and result in weld defects and unstable arc conditions. Too high flow

can cause air to be drawn into the gas column and contaminate the weld zone.

Use the correct shielding gas. Co2 is good for steel and offers good penetration characteristics, the weld

profile is narrower and slightly more raised than the weld profile obtained from Argon Co2 mixed gas.

Argon Co2 mix gas offers better weld ability for thin metals and has a wider range of setting tolerance on

the machine. Argon 80% Co2 20% is a good all round mix suitable for most applications.

Содержание GRAND MIG 351 MULTI SYN

Страница 33: ...4 4 Electrical schematic drawing DRIVER...

Страница 35: ...4 2 Troublesho oting...