ENG

| Instruction Manual

INSTALLATION

LK 440 EasyHeat should be placed indoors/under a roof and fully

protected from rain.

The integrated safety package including automatic air-bleed valve,

safety valve and connecting hoses, must be installed as shown in the

product diagram (see above). Relevant building standards and hot

water installation standards must be adhered to.

The safety valve’s outlet’s functioning must be ensured in the appro-

priate manner; refer to current hot water installation standards. No

thermometer is included in the standard kit. However, a thermometer

should be mounted on the pipe after the boiler.

The heating system must be arranged so that there is always a

flow through the cassette. Check to see that one or more of the

heating loops are always open.

SWITCHING ON

Before switching on, check to see that the heating system is filled

with water, air-bled and that the system’s operating pressure is

sufficient.

Check to see that the circulation pump is running by listening to

and testing the various pump speed settings.

THERMOSTAT OPERATION

Temperature regulation is via the boiler’s operational thermostat

(constant output temperature). The thermostat can be set up to a

maximum of 60 ºC.

Monitor the output temperature by means of a thermometer and

compare it to the set temperature.

CIRCULATION

For setting up the circulation pump, see separate instruction

”Grundfos UPM3 Auto 15/70”. Note that the pump is advanta-

geously set to work with constant pressure and that this must be

set manually according to separate instructions.

OVERHEATING PROTECTION

LK 440 EasyHeat is provided with built in overheating protection,

which cuts off the power at approx. 70 ºC.

To reset the overheating protection function, press button (12).

Resetting is possible after the boiler has cooled down to approx. 60

ºC. In the event of a repeated overheating, determine the cause of

the fault and fix it before restarting.

TRIP SWITCH, CIRCULATION PUMP

The circulation pump is protected by a 10 A Trip Switch (13). In the

event of the fuse tripping out, determine the cause of the fault and

fix it before restarting.

SAFETY VALVE

The safety valve must be tested at start-up and then at set inter-

vals 2-3 times per year. CAUTION: Take care when testing as the

out-flowing water/steam can cause scald injuries.

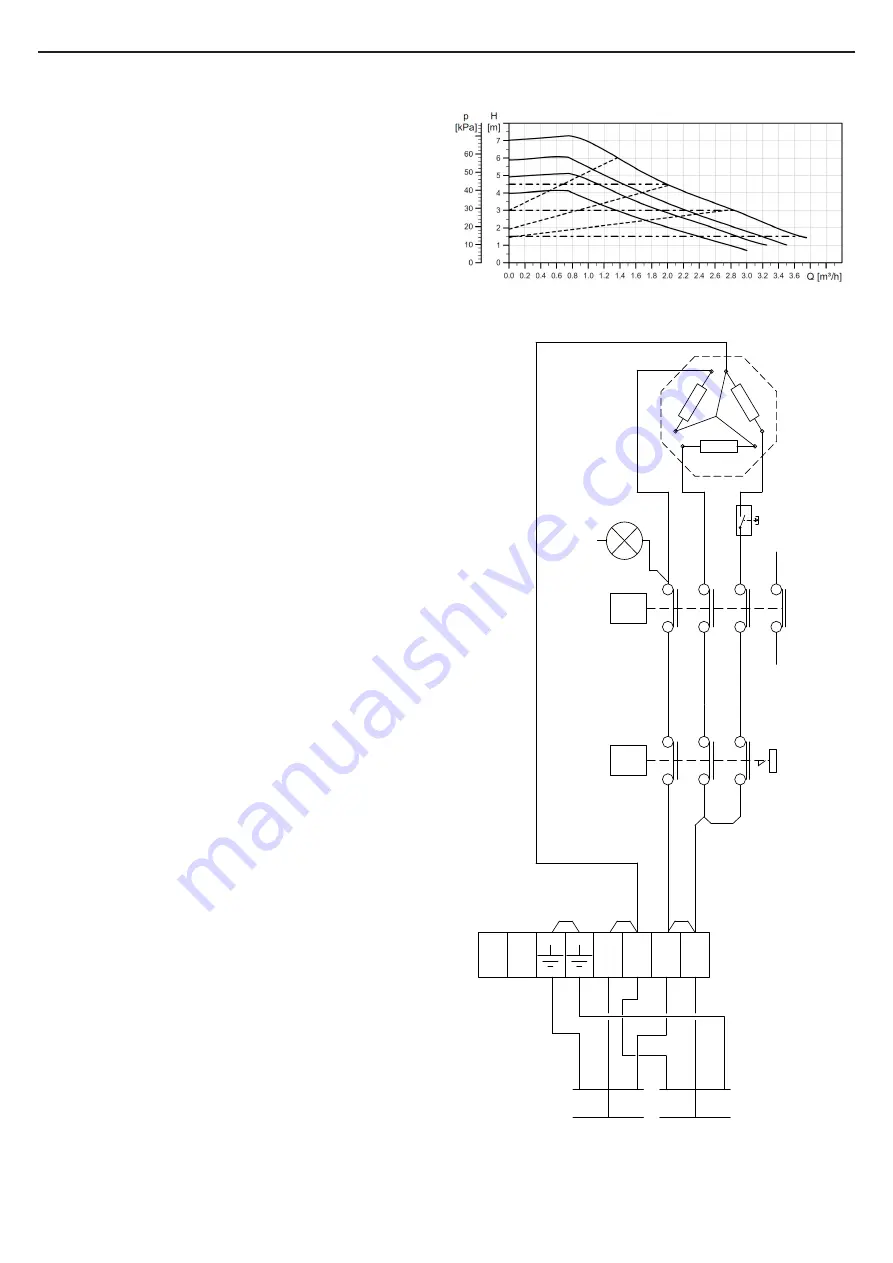

ELECTRIC CONNECTION DIAGRAM

PUMP GRAPH

11

12

21

22

31

32

41

42

0-60°C

T

11

12

21

22

31

32

STB

80°

1

3 kW

N N L L

3x1,5mm

2

1m

3x0,75mm

2

0,2m

Stickprop

cirkpump

N

Socket

Pump

2

www.lkarmatur.com