Subject

to

change

without

notice

Owner Manual

Operating Instructions

2.1A-30004-A02

LINCOLN GmbH & Co. KG Postfach 1263 D-69183 Walldorf Tel +49 (6227) 33-0 Fax +49 (6227) 33-259

Page 21 of 36

The maintenance is essentially limited to refilling the

reservoir with clean lubricant in good time. However,

check regularly whether the lubricant is really dispensed

to all the lubrication points.

Also check the main lines and lubricant feed lines for

damage and replace them, if necessary.

Note: Whenever work is done on the centralized lubrication

system, particular attention should be paid to absolute

cleanliness. Dirt in the system will cause problems.

For cleaning the system use benzine or petroleum. Do

not use tri-, perchloroethylene or similar solvents.

Also do not use polar organic solvents such as alcohol,

methylacohol, aceton or similar

Maintenance, Repair and Tests

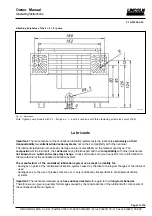

1011b93

Fig. 37 - Fill pump reservoir

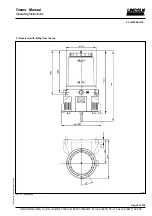

Pump filling

Maintenance

2 l, 4 l , 8 l - reservoirs

Fill the reservoir up to the Max. mark via the filling nipple or

a coupling or and adaptor.

It is possible to use greases up to penetration class NLGI 2.

Important!

The grease must be free from impurities and

must not be liable to change its consistency in the course of

time.

Attention: If the pump is filled via the upper filling opening,

switch off the power supply before starting filling.

Attention:

When filling the reservoir by

means of pumps with a large delive-

ry volume

do

not exceed the max. fil-

ling mark

.

Risk of bursting if the re-

servoir is overfilled.

Note: If the reservoir has been com-

pletely emptied, the pump may require up to 10 minutes be-

fore it operates with its full output.

Pump

Use only original LINCOLN spare parts for repair on the

pumps.

Return the pump to the factory for warranty work or major

repairs.

Pack defective printed circuit boards suitably and return to

the factory.

Repair